Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

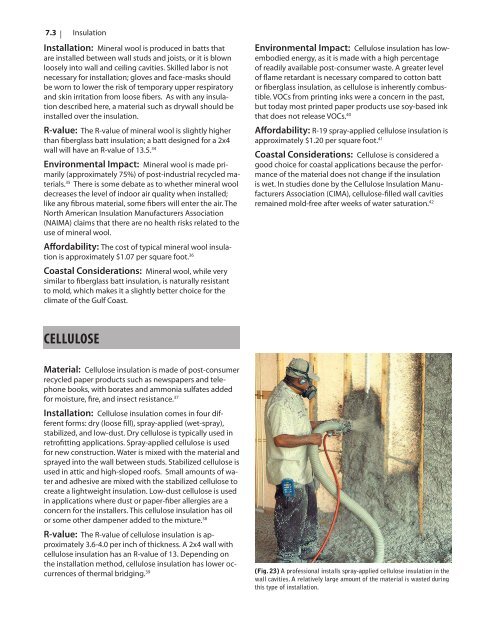

7.3 | InsulationInstallation: Mineral wool is produced in batts thatare installed between wall studs and joists, or it is blownloosely into wall and ceiling cavities. Skilled labor is notnecessary for installation; gloves and face-masks shouldbe worn to lower the risk of temporary upper respiratoryand skin irritation from loose fibers. As with any insulationdescribed here, a material such as drywall should beinstalled over the insulation.R-value: The R-value of mineral wool is slightly higherthan fiberglass batt insulation; a batt designed for a 2x4wall will have an R-value of 13.5. 34Environmental Impact: Mineral wool is made primarily(approximately 75%) of post-industrial recycled materials.35 There is some debate as to whether mineral wooldecreases the level of indoor air quality when installed;like any fibrous material, some fibers will enter the air. TheNorth American Insulation Manufacturers Association(NAIMA) claims that there are no health risks related to theuse of mineral wool.Affordability: The cost of typical mineral wool insulationis approximately $1.07 per square foot. 36Coastal Considerations: Mineral wool, while verysimilar to fiberglass batt insulation, is naturally resistantto mold, which makes it a slightly better choice for theclimate of the Gulf Coast.Environmental Impact: Cellulose insulation has lowembodiedenergy, as it is made with a high percentageof readily available post-consumer waste. A greater levelof flame retardant is necessary compared to cotton battor fiberglass insulation, as cellulose is inherently combustible.VOCs from printing inks were a concern in the past,but today most printed paper products use soy-based inkthat does not release VOCs. 40Affordability: R-19 spray-applied cellulose insulation isapproximately $1.20 per square foot. 41Coastal Considerations: Cellulose is considered agood choice for coastal applications because the performanceof the material does not change if the insulationis wet. In studies done by the Cellulose Insulation ManufacturersAssociation (CIMA), cellulose-filled wall cavitiesremained mold-free after weeks of water saturation. 42CELLULOSEMaterial: Cellulose insulation is made of post-consumerrecycled paper products such as newspapers and telephonebooks, with borates and ammonia sulfates addedfor moisture, fire, and insect resistance. 37Installation: Cellulose insulation comes in four differentforms: dry (loose fill), spray-applied (wet-spray),stabilized, and low-dust. Dry cellulose is typically used inretrofitting applications. Spray-applied cellulose is usedfor new construction. Water is mixed with the material andsprayed into the wall between studs. Stabilized cellulose isused in attic and high-sloped roofs. Small amounts of waterand adhesive are mixed with the stabilized cellulose tocreate a lightweight insulation. Low-dust cellulose is usedin applications where dust or paper-fiber allergies are aconcern for the installers. This cellulose insulation has oilor some other dampener added to the mixture. 38R-value: The R-value of cellulose insulation is approximately3.6-4.0 per inch of thickness. A 2x4 wall withcellulose insulation has an R-value of 13. Depending onthe installation method, cellulose insulation has lower occurrencesof thermal bridging. 39(Fig. 23) A professional installs spray-applied cellulose insulation in thewall cavities. A relatively large amount of the material is wasted duringthis type of installation.