Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

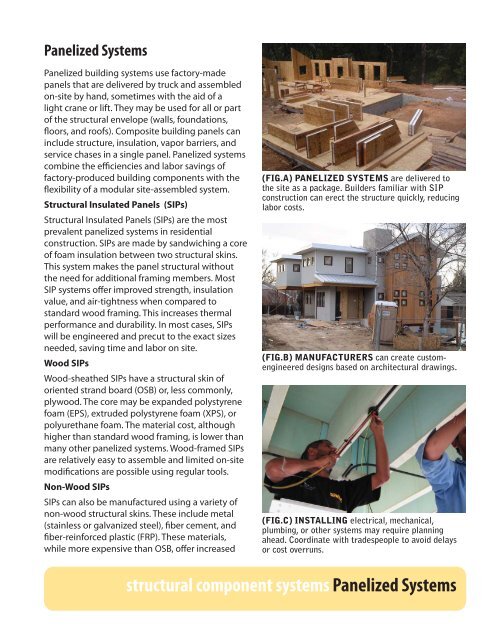

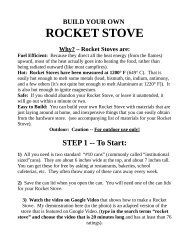

Panelized SystemsPanelized building systems use factory-madepanels that are delivered by truck and assembledon-site by hand, sometimes with the aid of alight crane or lift. They may be used for all or partof the structural envelope (walls, foundations,floors, and roofs). Composite building panels caninclude structure, insulation, vapor barriers, andservice chases in a single panel. Panelized systemscombine the efficiencies and labor savings offactory-produced building components with theflexibility of a modular site-assembled system.Structural Insulated Panels (SIPs)Structural Insulated Panels (SIPs) are the mostprevalent panelized systems in residentialconstruction. SIPs are made by sandwiching a coreof foam insulation between two structural skins.This system makes the panel structural withoutthe need for additional framing members. MostSIP systems offer improved strength, insulationvalue, and air-tightness when compared tostandard wood framing. This increases thermalperformance and durability. In most cases, SIPswill be engineered and precut to the exact sizesneeded, saving time and labor on site.Wood SIPsWood-sheathed SIPs have a structural skin oforiented strand board (OSB) or, less commonly,plywood. The core may be expanded polystyrenefoam (EPS), extruded polystyrene foam (XPS), orpolyurethane foam. The material cost, althoughhigher than standard wood framing, is lower thanmany other panelized systems. Wood-framed SIPsare relatively easy to assemble and limited on-sitemodifications are possible using regular tools.Non-Wood SIPsSIPs can also be manufactured using a variety ofnon-wood structural skins. These include metal(stainless or galvanized steel), fiber cement, andfiber-reinforced plastic (FRP). These materials,while more expensive than OSB, offer increased(FIG.A) PANELIZED SYSTEMS are delivered tothe site as a package. Builders familiar with SIPconstruction can erect the structure quickly, reducinglabor costs.(FIG.B) MANUFACTURERS can create customengineereddesigns based on architectural drawings.(FIG.C) INSTALLING electrical, mechanical,plumbing, or other systems may require planningahead. Coordinate with tradespeople to avoid delaysor cost overruns.structural component systems Panelized Systems