Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

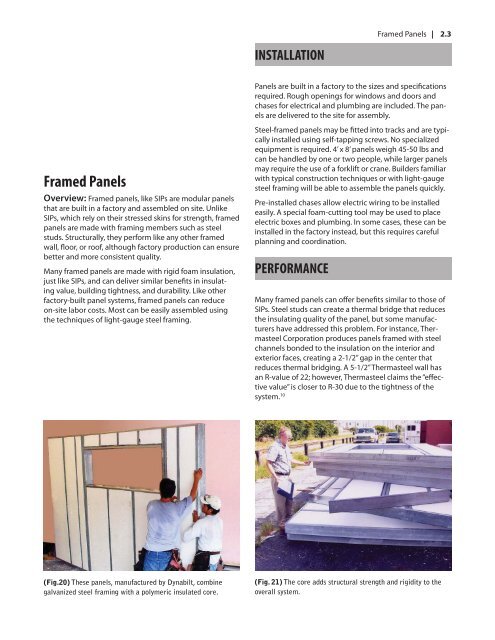

INSTALLATIONFramed Panels | 2.3Framed PanelsOverview: Framed panels, like SIPs are modular panelsthat are built in a factory and assembled on site. UnlikeSIPs, which rely on their stressed skins for strength, framedpanels are made with framing members such as steelstuds. Structurally, they perform like any other framedwall, floor, or roof, although factory production can ensurebetter and more consistent quality.Many framed panels are made with rigid foam insulation,just like SIPs, and can deliver similar benefits in insulatingvalue, building tightness, and durability. Like otherfactory-built panel systems, framed panels can reduceon-site labor costs. Most can be easily assembled usingthe techniques of light-gauge steel framing.Panels are built in a factory to the sizes and specificationsrequired. Rough openings for windows and doors andchases for electrical and plumbing are included. The panelsare delivered to the site for assembly.Steel-framed panels may be fitted into tracks and are typicallyinstalled using self-tapping screws. No specializedequipment is required. 4’ x 8’ panels weigh 45-50 lbs andcan be handled by one or two people, while larger panelsmay require the use of a forklift or crane. Builders familiarwith typical construction techniques or with light-gaugesteel framing will be able to assemble the panels quickly.Pre-installed chases allow electric wiring to be installedeasily. A special foam-cutting tool may be used to placeelectric boxes and plumbing. In some cases, these can beinstalled in the factory instead, but this requires carefulplanning and coordination.PERFORMANCEMany framed panels can offer benefits similar to those ofSIPs. Steel studs can create a thermal bridge that reducesthe insulating quality of the panel, but some manufacturershave addressed this problem. For instance, ThermasteelCorporation produces panels framed with steelchannels bonded to the insulation on the interior andexterior faces, creating a 2-1/2” gap in the center thatreduces thermal bridging. A 5-1/2” Thermasteel wall hasan R-value of 22; however, Thermasteel claims the “effectivevalue” is closer to R-30 due to the tightness of thesystem. 10(Fig.20) These panels, manufactured by Dynabilt, combinegalvanized steel framing with a polymeric insulated core.(Fig. 21) The core adds structural strength and rigidity to theoverall system.