- Page 3 and 4:

Mendel University in BrnoFaculty of

- Page 5 and 6:

Editors:Ing. Petr Škarpa, Ph.D., A

- Page 7 and 8:

MENDELNET 2013PrefaceThis year´s 2

- Page 9 and 10:

MENDELNET 2013EVALUATION OF BARE SO

- Page 11 and 12:

MENDELNET 2013DESIGN OF THE EQUIPME

- Page 13 and 14:

MENDELNET 2013HOW TO IMPRROVE THE C

- Page 15 and 16:

MENDELNET 2013PREDICTION OF TECHNOL

- Page 17 and 18:

MENDELNET 2013THE DEVICE FOR MECHAN

- Page 19 and 20:

MENDELNET 201317 | P age

- Page 21 and 22:

MENDELNET 201319 | P age

- Page 23 and 24:

MENDELNET 2013INTRODUCTIONThe proce

- Page 25 and 26:

MENDELNET 2013season. Year 2012 had

- Page 27 and 28:

MENDELNET 2013CONCLUSIONSThe aim of

- Page 29 and 30:

MENDELNET 2013WEED INFESTATION OF W

- Page 31 and 32:

MENDELNET 2013Crop sequence in seco

- Page 33 and 34:

MENDELNET 2013the soil in the early

- Page 35 and 36:

MENDELNET 2013INTRODUCTIONThe speci

- Page 37 and 38:

MENDELNET 2013The legend : The infl

- Page 39 and 40:

MENDELNET 2013DETERMINATION OF SPEC

- Page 41 and 42:

MENDELNET 2013Fig. 1 ASD Hand Held

- Page 43 and 44:

MENDELNET 2013Fig. 3 The Spectral R

- Page 45 and 46:

MENDELNET 2013CHANGES IN THE CONTEN

- Page 47 and 48:

MENDELNET 2013after exposure to abi

- Page 49 and 50:

MENDELNET 2013Hoffmann, P. 1988. De

- Page 51 and 52:

MENDELNET 2013INTRODUCTIONTradition

- Page 53 and 54:

MENDELNET 2013Explanation of abbrev

- Page 55 and 56:

MENDELNET 2013CHANGES OF WEED SPECT

- Page 57 and 58:

MENDELNET 2013Data collected in vin

- Page 59 and 60:

MENDELNET 2013REFERENCESANONYM, 200

- Page 61 and 62:

MENDELNET 2013INTRODUCTIONIn the Cz

- Page 63 and 64:

MENDELNET 2013Fig. 4: Concentration

- Page 65 and 66:

MENDELNET 2013SUGAR BEET YIELD PROD

- Page 67 and 68:

MENDELNET 2013RESULT AND DISCUSSION

- Page 69 and 70:

MENDELNET 2013and it was 18.41 t ha

- Page 71 and 72:

MENDELNET 2013DISTRIBUTION OF BARLE

- Page 73 and 74:

MENDELNET 2013RLD (cm.cm -3 )14.012

- Page 75 and 76:

MENDELNET 2013confirmed. In a shall

- Page 77 and 78:

MENDELNET 2013THE IMPACT OF VERMICO

- Page 79 and 80:

MENDELNET 2013fermentation, earthwo

- Page 81 and 82:

MENDELNET 2013Tab. 5 The significan

- Page 83 and 84:

MENDELNET 2013GUTIÉRREZ-MICELI, F.

- Page 85 and 86:

MENDELNET 2013INTRODUCTIONLupin was

- Page 87 and 88:

MENDELNET 2013Graph III. Average yi

- Page 89 and 90:

MENDELNET 2013Picture I. Demage of

- Page 91 and 92:

MENDELNET 2013COMPARISON OF THE ECO

- Page 93 and 94:

MENDELNET 2013Tab. 1 Rape varieties

- Page 95 and 96:

MENDELNET 2013Kč50 000,00Kč45 000

- Page 97 and 98:

MENDELNET 2013INTRODUCTIONSpecific

- Page 99 and 100:

MENDELNET 2013As can be seen from t

- Page 101 and 102:

MENDELNET 2013EVALUATED GRASS SOD A

- Page 103 and 104:

MENDELNET 2013RESULT AND DISCUSSION

- Page 105 and 106:

MENDELNET 2013REFERENCESBEARD, J.B.

- Page 107 and 108:

MENDELNET 2013INTRODUCTIONSemi-natu

- Page 109 and 110:

MENDELNET 2013Influence the intensi

- Page 111 and 112:

MENDELNET 2013THE CHANGES IN STAND

- Page 113 and 114:

MENDELNET 2013ZPS (%) = 0.5 * Σ |x

- Page 115 and 116:

MENDELNET 2013statistically signifi

- Page 117 and 118:

MENDELNET 2013INTRODUCTIONIn the fi

- Page 119 and 120:

MENDELNET 2013data relatively low.

- Page 121 and 122:

MENDELNET 2013LUKAS, V., NEUDERT, L

- Page 123 and 124:

MENDELNET 2013INTRODUCTIONNitrogen

- Page 125 and 126:

MENDELNET 2013This is evident from

- Page 127 and 128:

MENDELNET 2013MONITORING RUSTS OCCU

- Page 129 and 130:

MENDELNET 2013Fig. 1 Susceptibility

- Page 131 and 132:

MENDELNET 2013Roscher Ch., et al. (

- Page 133 and 134:

MENDELNET 2013INTRODUCTIONThe conce

- Page 135 and 136:

MENDELNET 2013DAISY and HERMES have

- Page 137 and 138:

MENDELNET 2013PALOSUO, T., KERSEBAU

- Page 139 and 140:

MENDELNET 2013INTRODUCTIONHops esse

- Page 141 and 142:

MENDELNET 2013According to Basařov

- Page 143 and 144:

MENDELNET 2013TESTING THE VITALITY

- Page 145 and 146:

MENDELNET 2013were compared with fi

- Page 147 and 148:

MENDELNET 2013and laboratory germin

- Page 149 and 150:

MENDELNET 2013EFFECTS OF SOIL CONDI

- Page 151 and 152:

MENDELNET 2013The experiment was co

- Page 153 and 154:

MENDELNET 2013SAIGUSA, M., YAMAMOTO

- Page 155 and 156:

MENDELNET 2013INTRODUCTIONHis Majes

- Page 157 and 158:

MENDELNET 2013Table 3. The cost, re

- Page 159 and 160:

MENDELNET 2013EVALUATION OF SYRIAN

- Page 161 and 162:

MENDELNET 2013genotypes overcame th

- Page 163 and 164:

MENDELNET 2013CONCLUSIONSThe evalua

- Page 165 and 166:

MENDELNET 2013INTRODUCTIONThe conte

- Page 167 and 168:

MENDELNET 2013Table 4. The effect o

- Page 169 and 170:

MENDELNET 2013fertilizer applicatio

- Page 171 and 172:

MENDELNET 2013169 | P age

- Page 173 and 174:

MENDELNET 2013171 | P age

- Page 175 and 176:

MENDELNET 2013INTRODUCTIONIt´s imp

- Page 177 and 178:

MENDELNET 2013demonstrated, that da

- Page 179 and 180:

MENDELNET 2013STABLE MICROCLIMATE I

- Page 181 and 182:

MENDELNET 2013and draught. The temp

- Page 183 and 184:

MENDELNET 2013consequence of consum

- Page 185 and 186:

MENDELNET 2013frequency (4 - 20 hea

- Page 187 and 188:

MENDELNET 2013INTRODUCTIONRaw milk

- Page 189 and 190:

MENDELNET 2013milker's hands, and a

- Page 191 and 192:

MENDELNET 2013INTRODUCTIONThe most

- Page 193 and 194:

MENDELNET 2013Tab. 1 gives results

- Page 195 and 196:

MENDELNET 2013EVALUATION OF THE TRA

- Page 197 and 198:

MENDELNET 2013Fig. 1 Development le

- Page 199 and 200:

MENDELNET 2013USING ICSI IN DIFFERE

- Page 201 and 202:

MENDELNET 2013Oocyte handlingCumula

- Page 203 and 204:

MENDELNET 2013CONCLUSIONSThe presen

- Page 205 and 206:

MENDELNET 2013IN-VITRO ANTIBACTERIA

- Page 207 and 208:

MENDELNET 2013Tab.1. zone of inhibi

- Page 209 and 210:

MENDELNET 2013COMPARISON OF LACTOSE

- Page 211 and 212:

MENDELNET 2013bound to DNA. Chlorid

- Page 213 and 214:

MENDELNET 2013HARDING, F., 1996: Mi

- Page 215 and 216:

MENDELNET 2013INTRODUCTIONEuropean

- Page 217 and 218:

MENDELNET 2013CONCLUSIONSThe aim of

- Page 219 and 220:

MENDELNET 2013INTRODUCTIONFish lipi

- Page 221 and 222:

MENDELNET 2013The effect of fish or

- Page 223 and 224:

MENDELNET 2013COMPARISON OF GRAZING

- Page 225 and 226:

MENDELNET 2013E GQ = Σ(D * FV) / 8

- Page 227 and 228:

MENDELNET 2013CONCLUSIONSAccording

- Page 229 and 230:

MENDELNET 2013INTRODUCTIONThere are

- Page 231 and 232:

MENDELNET 2013thoroughbred horses,

- Page 233 and 234:

MENDELNET 2013Tab. 3 Line-based shi

- Page 235 and 236:

MENDELNET 2013THE EFFECT OF FEEDING

- Page 237 and 238:

MENDELNET 2013Fig. 1 - Digital vill

- Page 239 and 240:

MENDELNET 2013KIDD, M. T., et al.,

- Page 241 and 242:

MENDELNET 2013INTRODUCTIONIn biomed

- Page 243 and 244:

MENDELNET 2013lipid droplets in mat

- Page 245 and 246:

MENDELNET 2013t(%)100ABab0MHCMLCVal

- Page 247 and 248:

MENDELNET 2013HIRAGA, K., HOSHINO,

- Page 249 and 250:

MENDELNET 2013INFLUENCE OF DIETARY

- Page 251 and 252:

MENDELNET 2013Tab. 1 Content of ani

- Page 253 and 254:

MENDELNET 2013THE EFFECT OF BROILER

- Page 255 and 256:

MENDELNET 2013The observation was c

- Page 257 and 258:

MENDELNET 2013incidence of contusio

- Page 259 and 260:

MENDELNET 2013INTRODUCTIONBreeding

- Page 261 and 262:

MENDELNET 2013satisfactory, however

- Page 263 and 264:

MENDELNET 2013ROOTWELT, V., REKSEN,

- Page 265 and 266:

MENDELNET 2013INTRODUCTIONHucul hor

- Page 267 and 268:

MENDELNET 2013• statistically eva

- Page 269 and 270:

MENDELNET 2013REFERENCESDUŠEK, J.

- Page 271 and 272:

MENDELNET 2013INTRODUCTIONIn the la

- Page 273 and 274:

MENDELNET 2013Table 2. Body weight

- Page 275 and 276:

MENDELNET 2013INTERACTIONS BETWEEN

- Page 277 and 278:

MENDELNET 2013Fig. 3: The effect of

- Page 279 and 280:

MENDELNET 2013ŘEZÁČ, P., VIZIOV

- Page 281 and 282:

MENDELNET 2013INTRODUCTIONMilk prod

- Page 283 and 284:

MENDELNET 2013Values of coefficient

- Page 285 and 286:

MENDELNET 2013283 | P age

- Page 287 and 288:

MENDELNET 2013285 | P age

- Page 289 and 290:

MENDELNET 2013INTRODUCTIONSoil hydr

- Page 291 and 292:

MENDELNET 2013Fig. 1 Mineral nitrog

- Page 293 and 294:

MENDELNET 2013DESIGN OF THE EQUIPME

- Page 295 and 296:

MENDELNET 2013These probes were pla

- Page 297 and 298:

MENDELNET 2013CONCLUSIONSOur experi

- Page 299 and 300:

MENDELNET 2013INTRODUCTIONAccelerat

- Page 301 and 302:

MENDELNET 2013The maximum capillary

- Page 303 and 304:

MENDELNET 2013THE INTENSITY OF WATE

- Page 305 and 306:

MENDELNET 2013This paper will addre

- Page 307 and 308:

MENDELNET 2013L-factor was calculat

- Page 309 and 310:

MENDELNET 2013most fertile agricult

- Page 311 and 312:

MENDELNET 2013INTRODUCTIONCarbonate

- Page 313 and 314:

MENDELNET 2013correlated only with

- Page 315 and 316:

MENDELNET 2013PAN, CH., ZHAO, H., Z

- Page 317 and 318:

MENDELNET 2013INTRODUCTIONAgricultu

- Page 319 and 320:

MENDELNET 2013CalciumEvaluationCa m

- Page 321 and 322:

MENDELNET 2013CarbonatesFig. 7: Con

- Page 323 and 324:

MENDELNET 2013ŠKARPA P., 2010: Lab

- Page 325 and 326:

MENDELNET 2013INTRODUCTIONIntercrop

- Page 327 and 328:

MENDELNET 2013Fig. 2 Production of

- Page 329 and 330:

MENDELNET 2013THE POSSIBILITY OF US

- Page 331 and 332:

MENDELNET 2013109. Content of carbo

- Page 333 and 334:

MENDELNET 2013FALLOPIA JAPONICA HOU

- Page 335 and 336:

MENDELNET 2013333 | P age

- Page 337 and 338:

MENDELNET 2013BARNEY, J. N., et al.

- Page 339 and 340:

MENDELNET 2013INTRODUCTIONThis work

- Page 341 and 342:

MENDELNET 2013and higher concentrat

- Page 343 and 344:

MENDELNET 2013A MATHEMATICAL MODEL

- Page 345 and 346:

MENDELNET 2013Coefficients of (1) w

- Page 347 and 348:

MENDELNET 2013CONCLUSIONSAlthough t

- Page 349 and 350:

MENDELNET 2013THE USE OF COMPOST TO

- Page 351 and 352:

MENDELNET 2013Topsoil and subsoil w

- Page 353 and 354:

MENDELNET 2013L. Plošek, J. Elbl,

- Page 355 and 356:

MENDELNET 2013INTRODUCTIONTests of

- Page 357 and 358:

MENDELNET 2013Table 2. Preparation

- Page 359 and 360:

MENDELNET 2013ANALYSIS OF SPRING BA

- Page 361 and 362:

MENDELNET 2013ET. During the growin

- Page 363 and 364:

MENDELNET 2013Evapotranspiration ra

- Page 365 and 366:

MENDELNET 2013INTRODUCTIONThe aim o

- Page 367 and 368:

MENDELNET 2013SOustava“ - Agromet

- Page 369 and 370:

MENDELNET 2013THE HISTORY AND TRADI

- Page 371 and 372:

MENDELNET 2013spol. s.r.o. Monitore

- Page 373 and 374:

MENDELNET 2013ČESKÝ STATISTICKÝ

- Page 375 and 376:

MENDELNET 2013INTRODUCTIONAgricultu

- Page 377 and 378:

MENDELNET 2013• Definition of ele

- Page 379 and 380:

MENDELNET 2013The results are telli

- Page 381 and 382:

MENDELNET 2013DIFFERENCE BETWEEN TH

- Page 383 and 384:

MENDELNET 2013Picture 1 Cadastral V

- Page 385 and 386:

MENDELNET 2013Fig. 1 Degree of eros

- Page 387 and 388:

MENDELNET 2013INTRODUCTIONSoil eros

- Page 389 and 390:

MENDELNET 2013stable forms of organ

- Page 391 and 392:

MENDELNET 2013land use, pesticides,

- Page 393 and 394:

MENDELNET 2013EFFECTS OF UV RADIATI

- Page 395 and 396:

MENDELNET 2013Flysch Godulian sands

- Page 397 and 398:

MENDELNET 2013CONCLUSIONSUV-B radia

- Page 399 and 400:

MENDELNET 2013COMPARISON OF METHODS

- Page 401 and 402:

MENDELNET 2013sum of the detected a

- Page 403 and 404:

MENDELNET 2013same predictive value

- Page 405 and 406:

MENDELNET 2013Section - Rural Devel

- Page 407 and 408:

MENDELNET 2013THE IMPACT OF WINTER

- Page 409 and 410:

MENDELNET 2013accommodation due to

- Page 411 and 412:

MENDELNET 2013THE USE OF SOLAR ENER

- Page 413 and 414:

MENDELNET 2013The general data of t

- Page 415 and 416:

MENDELNET 2013The photovoltaic powe

- Page 417 and 418:

MENDELNET 2013FUNCTION OF AGRICULTU

- Page 419 and 420:

MENDELNET 2013Fig. 1. The definitio

- Page 421 and 422:

MENDELNET 2013EconomicEconomic• E

- Page 423 and 424:

MENDELNET 2013RENEWABLE ENERGY, AS

- Page 425 and 426:

MENDELNET 2013After analysing the d

- Page 427 and 428:

MENDELNET 2013Rural settlements are

- Page 429 and 430:

MENDELNET 2013THE IMPACT OF A ROAD

- Page 431 and 432:

MENDELNET 2013Three types of CES we

- Page 433 and 434:

MENDELNET 2013stream [9] and Kamenn

- Page 435 and 436:

MENDELNET 2013THE PROPOSAL OF LANDS

- Page 437 and 438:

MENDELNET 2013MATERIAL AND METHODST

- Page 439 and 440:

MENDELNET 2013As for our own resear

- Page 441 and 442:

MENDELNET 2013occur more often and

- Page 443 and 444:

MENDELNET 2013The arrangements how

- Page 445 and 446:

MENDELNET 2013Layers of basic mapsQ

- Page 447 and 448:

MENDELNET 2013INTRODUCTIONLand cons

- Page 449 and 450:

MENDELNET 2013reforms, all balks, b

- Page 451 and 452:

MENDELNET 2013ASSESSMENT OF CHANGES

- Page 453 and 454:

MENDELNET 2013meets criteria of sel

- Page 455 and 456:

MENDELNET 2013unutilization. Extens

- Page 457 and 458:

MENDELNET 2013INTRODUCTIONSince joi

- Page 459 and 460:

MENDELNET 2013On the contrary a neg

- Page 461 and 462:

MENDELNET 2013THEORETICAL AND METHO

- Page 463 and 464:

MENDELNET 2013RESULT AND DISCUSSION

- Page 465 and 466:

MENDELNET 2013amount of information

- Page 467 and 468:

MENDELNET 2013IMPLEMENTING THE STAT

- Page 469 and 470:

MENDELNET 2013practice example can

- Page 471 and 472:

MENDELNET 2013elaborating the docum

- Page 473 and 474:

MENDELNET 2013SOUTH-MORAVIAN COUNTR

- Page 475 and 476:

MENDELNET 2013Tab. 1 Number of devi

- Page 477 and 478:

MENDELNET 2013REFERENCES1) ADAMCOV

- Page 479 and 480:

MENDELNET 2013INTRODUCTIONDespite o

- Page 481 and 482:

MENDELNET 2013RESULTS FROM SWOT ANA

- Page 483 and 484:

MENDELNET 2013PRIŠENK, J. and BORE

- Page 485 and 486:

MENDELNET 2013INTRODUCTIONIt has be

- Page 487 and 488:

MENDELNET 2013RESULT AND DISCUSSION

- Page 489 and 490:

MENDELNET 2013THE ECONOMIC AND SOCI

- Page 491 and 492:

MENDELNET 2013citizen (the buyer) i

- Page 493 and 494:

MENDELNET 2013of South Moravian Reg

- Page 495 and 496:

MENDELNET 2013INTRODUCTIONWith the

- Page 497 and 498:

MENDELNET 2013Fig.1. Map of present

- Page 499 and 500:

MENDELNET 2013Fig.2 Hydric potentia

- Page 501 and 502:

MENDELNET 2013EVALUATION OF CURRENT

- Page 503 and 504:

MENDELNET 2013through prepared ques

- Page 505 and 506:

MENDELNET 2013example; it won the s

- Page 507 and 508:

MENDELNET 2013THE DEVELOPMENT AND C

- Page 509 and 510:

MENDELNET 2013countries was evaluat

- Page 511 and 512:

MENDELNET 2013itself. While impleme

- Page 513 and 514:

MENDELNET 2013INTRODUCTIONThe Czech

- Page 515 and 516:

MENDELNET 2013Fig. 3 Map of the Cze

- Page 517 and 518:

MENDELNET 2013CONCLUSIONSProduction

- Page 519 and 520:

MENDELNET 2013INTRODUCTIONLandscape

- Page 521 and 522:

MENDELNET 2013The 3-level planning

- Page 523 and 524:

MENDELNET 2013THE PROPOSAL OF THE W

- Page 525 and 526:

MENDELNET 2013RESULT AND DISCUSSION

- Page 527 and 528:

MENDELNET 2013demonstrates that env

- Page 529 and 530:

MENDELNET 2013INTRODUCTIONLand cons

- Page 531 and 532:

MENDELNET 2013Fig. 2: Reconnaissanc

- Page 533 and 534:

MENDELNET 2013MEASUREMENT OF EMISSI

- Page 535 and 536:

MENDELNET 2013Tab. 1: The range and

- Page 537 and 538:

MENDELNET 2013However, the comparis

- Page 539 and 540:

MENDELNET 2013INDICATORS OF THE QUA

- Page 541 and 542:

MENDELNET 2013Tab. 1 Index of livin

- Page 543 and 544:

MENDELNET 2013CONCLUSIONSResults of

- Page 545 and 546:

MENDELNET 2013INTRODUCTIONTourism d

- Page 547 and 548:

MENDELNET 2013Disadvantages are rep

- Page 549 and 550:

MENDELNET 2013547 | P age

- Page 551 and 552:

MENDELNET 2013549 | P age

- Page 553 and 554:

MENDELNET 2013INTRODUCTIONThe therm

- Page 555 and 556:

MENDELNET 2013RESULT AND DISCUSSION

- Page 557 and 558:

MENDELNET 2013FUSARIUM SPECIES SPEC

- Page 559 and 560:

MENDELNET 2013Table 1: Climatic reg

- Page 561 and 562:

MENDELNET 2013Figure 3: Frequency o

- Page 563 and 564:

MENDELNET 2013IOOS, R. - BELHADJ, S

- Page 565 and 566:

MENDELNET 2013MONITORING OF PHTHALA

- Page 567 and 568:

MENDELNET 2013RESULTS AND DISCUSSIO

- Page 569 and 570:

MENDELNET 2013REFERENCESBRIMER, L.,

- Page 571 and 572:

MENDELNET 2013INTRODUCTIONSmall far

- Page 573 and 574:

MENDELNET 2013Tab. 4: Counts of mic

- Page 575 and 576:

MENDELNET 2013significant, the extr

- Page 577 and 578:

MENDELNET 2013THE USING OF NEAR INF

- Page 579 and 580:

MENDELNET 2013optical probe by 100

- Page 581 and 582:

MENDELNET 2013CONCLUSIONSThe device

- Page 583 and 584:

MENDELNET 2013INTRODUCTIONLipids wi

- Page 585 and 586:

MENDELNET 2013High acid content of

- Page 587 and 588:

MENDELNET 2013DYNAMICS OF CHANGES I

- Page 589 and 590:

MENDELNET 2013The barley crop was h

- Page 591 and 592:

MENDELNET 2013Fig. 5: B-hordeins (%

- Page 593 and 594:

MENDELNET 2013HŘIVNA L., GREGOR T.

- Page 595 and 596:

MENDELNET 2013INTRODUCTIONPhthalic

- Page 597 and 598:

MENDELNET 2013concentrations of DBP

- Page 599 and 600:

MENDELNET 2013YIELD AND QUALITY OF

- Page 601 and 602:

MENDELNET 2013variants is shown in

- Page 603 and 604:

MENDELNET 2013%22,021,020,019,018,0

- Page 605 and 606:

MENDELNET 2013EGGSHELL CRACK DETECT

- Page 607 and 608:

MENDELNET 2013It consists of three

- Page 609 and 610:

MENDELNET 2013magnitude values from

- Page 611 and 612:

MENDELNET 2013ANTIMICROBIAL PROTECT

- Page 613 and 614:

MENDELNET 2013filled by one drop of

- Page 615 and 616:

MENDELNET 2013TRIPATHI, P. AND N.K.

- Page 617 and 618:

MENDELNET 2013INTRODUCTIONWhey or m

- Page 619 and 620:

MENDELNET 2013values of these sampl

- Page 621 and 622:

MENDELNET 2013The microbiological r

- Page 623 and 624:

MENDELNET 2013THE INFLUENCE OF POLY

- Page 625 and 626:

MENDELNET 2013verified by the seque

- Page 627 and 628:

MENDELNET 2013JUMP D.B., 2008: N-3

- Page 629 and 630:

MENDELNET 2013Section - Plant Biolo

- Page 631 and 632:

MENDELNET 2013NON-DESTRUCTIVE ANALY

- Page 633 and 634:

MENDELNET 2013Graph. 1 Content of f

- Page 635 and 636:

MENDELNET 2013CONCLUSIONSThe highes

- Page 637 and 638:

MENDELNET 2013INTRODUCTIONThe occur

- Page 639 and 640:

MENDELNET 2013-2815 Calculated13897

- Page 641 and 642:

MENDELNET 2013EFFECT OF STRIGOLACTO

- Page 643 and 644:

MENDELNET 2013For the assessment of

- Page 645 and 646:

MENDELNET 2013PAPONOV, I. A. TEALE,

- Page 647 and 648:

MENDELNET 2013INTRODUCTIONMilk this

- Page 649 and 650:

MENDELNET 2013CitoniceFRAA8400007 8

- Page 651 and 652:

MENDELNET 2013DETERMINATION OF OIL

- Page 653 and 654:

MENDELNET 2013extraction, the secon

- Page 655 and 656:

MENDELNET 2013The blue curve (upper

- Page 657 and 658:

MENDELNET 2013INTRODUCTIONThe dynam

- Page 659 and 660:

MENDELNET 2013auxin source. These d

- Page 661 and 662:

MENDELNET 2013PREDICTION OF TECHNOL

- Page 663 and 664:

MENDELNET 2013Total volume of PCR r

- Page 665 and 666:

MENDELNET 2013DONG, H., COX, T. S.,

- Page 667 and 668:

MENDELNET 2013INTRODUCTIONCereals a

- Page 669 and 670:

MENDELNET 2013demonstrated in genot

- Page 671 and 672:

MENDELNET 2013INTERACTIVE EFFECTS O

- Page 673 and 674:

MENDELNET 2013number) were performe

- Page 675 and 676:

MENDELNET 2013CONCLUSIONSElevated [

- Page 677 and 678:

MENDELNET 2013INTRODUCTIONAnthocyan

- Page 679 and 680:

MENDELNET 2013possible that a copy

- Page 681 and 682:

MENDELNET 2013INTRODUCTIONBesides t

- Page 683 and 684:

MENDELNET 2013DFR expressionThe exp

- Page 685 and 686:

MENDELNET 2013683 | P age

- Page 687 and 688:

MENDELNET 2013685 | P age

- Page 689 and 690:

MENDELNET 2013INTRODUCTIONThe under

- Page 691 and 692:

MENDELNET 2013Tab. 3 The results of

- Page 693 and 694:

MENDELNET 2013REAL-TIME SENSING OF

- Page 695 and 696:

MENDELNET 2013Heart preparationFirs

- Page 697 and 698:

MENDELNET 2013Li, L., T. L. M. ten

- Page 699 and 700:

MENDELNET 2013INTRODUCTIONBirds are

- Page 701 and 702:

MENDELNET 2013CONCLUSIONSThis work

- Page 703 and 704:

MENDELNET 2013THE EFFECT OF MOLYBDE

- Page 705 and 706:

MENDELNET 2013statistical program S

- Page 707 and 708:

MENDELNET 2013REFERENCESBERSÉNYI,A

- Page 709 and 710:

MENDELNET 2013INTRODUCTIONIn compar

- Page 711 and 712:

MENDELNET 2013Flight activity of do

- Page 713 and 714:

MENDELNET 2013ARACHNOFAUNA OF TREES

- Page 715 and 716:

MENDELNET 2013Fig. 2: Distribution

- Page 717 and 718:

MENDELNET 2013MILLER F., 1971: Řá

- Page 719 and 720:

MENDELNET 2013INTRODUCTIONThe way o

- Page 721 and 722:

MENDELNET 2013Calathus micropterus

- Page 723 and 724:

MENDELNET 2013HOW ABOUT EATING THE

- Page 725 and 726:

MENDELNET 2013In the first analyse

- Page 727 and 728:

MENDELNET 2013MARKOVÁ, Z. a HEJDA,

- Page 729 and 730:

MENDELNET 2013INTRODUCTIONAll horse

- Page 731 and 732:

MENDELNET 2013phenotypically as dar

- Page 733 and 734:

MENDELNET 2013underwhite Gene (uw)U

- Page 735 and 736:

MENDELNET 2013INTRODUCTIONMeat qual

- Page 737 and 738:

MENDELNET 2013The substitution C878

- Page 739 and 740:

MENDELNET 2013ICHTHYOLOGICAL SURVEY

- Page 741 and 742:

MENDELNET 2013RESULT AND DISCUSSION

- Page 743 and 744:

MENDELNET 2013the mostly balanced f

- Page 745 and 746:

MENDELNET 2013THE EFFECT OF HEAVY M

- Page 747 and 748:

MENDELNET 201324 h on a shaker at 4

- Page 749 and 750:

MENDELNET 2013Elased, K. M., T. S.

- Page 751 and 752:

MENDELNET 2013INTRODUCTIONRecently,

- Page 753 and 754:

MENDELNET 2013caudal fin is needed

- Page 755 and 756:

MENDELNET 20133D CHIP AS A TOOL FOR

- Page 757 and 758:

MENDELNET 2013Fabrication of 3D mic

- Page 759 and 760:

MENDELNET 2013CONCLUSIONSWe describ

- Page 761 and 762:

MENDELNET 2013INTRODUCTIONSeveral f

- Page 763 and 764:

MENDELNET 2013Tab.3: Absolute and r

- Page 765 and 766:

MENDELNET 2013loci on Sus scrofa ch

- Page 767 and 768:

MENDELNET 2013INTRODUCTIONThe dog i

- Page 769 and 770:

MENDELNET 2013Fig. 1 The negative c

- Page 771 and 772:

MENDELNET 2013ECOLOGY AND HABITAT P

- Page 773 and 774:

MENDELNET 2013specimens. Data on th

- Page 775 and 776:

MENDELNET 2013CONCLUSIONSThe evalua

- Page 777 and 778:

MENDELNET 2013INTRODUCTIONIt is nec

- Page 779 and 780:

MENDELNET 2013Fig. 2: Nucleus movin

- Page 781 and 782:

MENDELNET 2013distance comparing to

- Page 783 and 784:

MENDELNET 2013INTRODUCTIONThe count

- Page 785 and 786:

MENDELNET 2013Tab .2LocalityVyšavy

- Page 787 and 788:

MENDELNET 2013Tab. 4LocalityNosisla

- Page 789 and 790:

MENDELNET 2013REFERENCESBrychta, V.

- Page 791 and 792:

MENDELNET 2013INTRODUCTIONMammary g

- Page 793 and 794:

MENDELNET 2013Fig. 2. Proportion of

- Page 795 and 796:

MENDELNET 2013THE FOOD OF PERCH (PE

- Page 797 and 798:

MENDELNET 2013Cladocerans were domi

- Page 799 and 800: MENDELNET 2013PETERKA, J., MATĚNA,

- Page 801 and 802: MENDELNET 2013INTRODUCTIONFrom a pe

- Page 803 and 804: MENDELNET 2013REFERENCESDIENER, S.,

- Page 805 and 806: MENDELNET 2013Section - Techniques

- Page 807 and 808: MENDELNET 2013EVALUATION OF POLLUTI

- Page 809 and 810: MENDELNET 2013relief valve into the

- Page 811 and 812: MENDELNET 2013the end of laboratory

- Page 813 and 814: MENDELNET 2013INTRODUCTIONAgricultu

- Page 815 and 816: MENDELNET 2013CONCLUSIONSFig. 1 Box

- Page 817 and 818: MENDELNET 2013CONCEPTUAL SOLUTION O

- Page 819 and 820: MENDELNET 2013Chemical parameters:

- Page 821 and 822: MENDELNET 2013Focusing on the econo

- Page 823 and 824: MENDELNET 2013INTRODUCTIONHigher de

- Page 825 and 826: MENDELNET 2013RESULT AND DISCUSSION

- Page 827 and 828: MENDELNET 2013REFERENCESBAUER, F.,

- Page 829 and 830: MENDELNET 2013INTRODUCTIONToday´s

- Page 831 and 832: MENDELNET 2013Fig. 1 - Embedded sys

- Page 833 and 834: MENDELNET 2013From the above it is

- Page 835 and 836: MENDELNET 2013INTRODUCTIONNowadays,

- Page 837 and 838: MENDELNET 2013Fig. 1. The average n

- Page 839 and 840: MENDELNET 2013LABORATORY MEASUREMEN

- Page 841 and 842: MENDELNET 2013Electronic thermomete

- Page 843 and 844: MENDELNET 2013Fig. 3 Graph of depen

- Page 845 and 846: MENDELNET 2013INTRODUCTIONThe devel

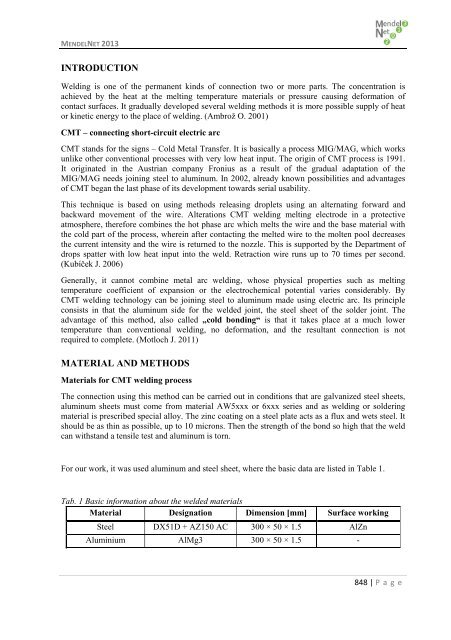

- Page 847 and 848: MENDELNET 2013Graph no. 2 represent

- Page 849: MENDELNET 2013ANALYSIS OF MODERN ME

- Page 853 and 854: MENDELNET 2013SampleTab. 2 Overview

- Page 855 and 856: MENDELNET 2013INTRODUCTIONCarbon di

- Page 857 and 858: MENDELNET 2013fan power is performe

- Page 859 and 860: MENDELNET 2013TRACTOR ENGINE MODES

- Page 861 and 862: MENDELNET 2013Technical parameters

- Page 863 and 864: MENDELNET 2013Measurement confirmed

- Page 865 and 866: MENDELNET 2013INTRODUCTIONMain natu

- Page 867 and 868: MENDELNET 2013Fig. 2 - Sub-region t

- Page 869 and 870: MENDELNET 2013DEVELOPMENT OF SEEDER

- Page 871 and 872: MENDELNET 2013RESULTS AND DISCUSSIO

- Page 873 and 874: MENDELNET 2013The depth controlling

- Page 875 and 876: MENDELNET 2013INTRODUCTIONInfluence

- Page 877 and 878: MENDELNET 2013In graph 1 is the sma

- Page 879 and 880: MENDELNET 2013DESIGN OF A MONITORIN

- Page 881 and 882: MENDELNET 2013Selection of such typ

- Page 883 and 884: MENDELNET 2013REFERENCESVITÁZEK, I

- Page 885 and 886: MENDELNET 2013INTRODUCTIONFertilisa

- Page 887 and 888: MENDELNET 2013particle-size distrib

- Page 889 and 890: MENDELNET 2013ŠIMA, T. & DUBEŇOV

- Page 891 and 892: MENDELNET 2013INTRODUCTIONBee hive

- Page 893 and 894: MENDELNET 2013RMSmV1601401201008060

- Page 895 and 896: MENDELNET 2013UTILISATION OF PROGRA

- Page 897 and 898: MENDELNET 2013Ivan (1989) stated th

- Page 899 and 900: MENDELNET 2013Fig. 4 Manoeuvre - ri

- Page 901 and 902:

MENDELNET 2013EFFECT OF THE SATELLI

- Page 903 and 904:

MENDELNET 2013In both experiments w

- Page 905 and 906:

MENDELNET 2013operation 125 measure

- Page 907 and 908:

MENDELNET 2013905 | P age

- Page 909 and 910:

MENDELNET 2013907 | P age

- Page 911 and 912:

MENDELNET 2013INTRODUCTIONTheranost

- Page 913 and 914:

MENDELNET 2013Fig. 1 Characterizati

- Page 915 and 916:

MENDELNET 2013LIPOSOMES AS DRUG CAR

- Page 917 and 918:

MENDELNET 2013microplate in various

- Page 919 and 920:

MENDELNET 2013Fig. 3: Differential

- Page 921 and 922:

MENDELNET 2013THE ROLE OF NITRIC OX

- Page 923 and 924:

MENDELNET 2013one such compound bec

- Page 925 and 926:

MENDELNET 2013Kováčik, J., Klejdu

- Page 927 and 928:

MENDELNET 2013INTRODUCTIONWater is

- Page 929 and 930:

MENDELNET 2013For all the heavy met

- Page 931 and 932:

MENDELNET 2013THE USE OF NANOTECHNO

- Page 933 and 934:

MENDELNET 2013During the analysis 2

- Page 935 and 936:

MENDELNET 2013REFERENCES[1] RANDALL

- Page 937 and 938:

MENDELNET 2013INTRODUCTIONQuantum d

- Page 939 and 940:

MENDELNET 2013Fig. 2: The staining

- Page 941 and 942:

MENDELNET 2013REFERENCESAlgar, W. R

- Page 943 and 944:

MENDELNET 2013INTRODUCTIONGunshot r

- Page 945 and 946:

MENDELNET 2013correlation is seen b

- Page 947 and 948:

MENDELNET 2013ELECTROCHEMICAL DETEC

- Page 949 and 950:

MENDELNET 2013Electrochemical detec

- Page 951 and 952:

MENDELNET 2013Krizkova, S., I. Fabr

- Page 953 and 954:

MENDELNET 2013HavlováL.721 Kadlč

- Page 955 and 956:

MENDELNET 2013Procházková B. 48

- Page 957:

MENDELNET 2013Name of publication: