- Page 1:

Goulds PumpsInstallation, Operation

- Page 4 and 5:

Table of ContentsImpeller-clearance

- Page 6 and 7:

Introduction and SafetyIntroduction

- Page 8 and 9:

Introduction and Safety (Continued)

- Page 10 and 11:

Introduction and Safety (Continued)

- Page 12 and 13:

Introduction and Safety (Continued)

- Page 14 and 15:

Introduction and Safety (Continued)

- Page 16 and 17:

Introduction and Safety (Continued)

- Page 18 and 19:

Introduction and Safety (Continued)

- Page 20 and 21:

Transportation and Storage (Continu

- Page 22 and 23:

Product DescriptionProduct Descript

- Page 24 and 25:

Product Description (Continued)Cove

- Page 26 and 27:

Product Description (Continued)Tabl

- Page 28 and 29:

InstallationInstallationPreinstalla

- Page 30 and 31:

Installation (Continued)Piping chec

- Page 32 and 33:

Installation (Continued)Liquid sour

- Page 34 and 35:

Installation (Continued)Example: Di

- Page 36 and 37:

Installation (Continued)d) Make sur

- Page 38 and 39:

Installation (Continued)76152341. U

- Page 40 and 41:

Installation (Continued)Baseplate-l

- Page 42 and 43:

Installation (Continued)WhenPeriodi

- Page 44 and 45:

Installation (Continued)1. Set the

- Page 46 and 47:

Installation (Continued)C-face adap

- Page 48 and 49:

Commissioning, Startup, Operation,

- Page 50 and 51:

Commissioning, Startup, Operation,

- Page 52 and 53:

Commissioning, Startup, Operation,

- Page 54 and 55: Commissioning, Startup, Operation,

- Page 56 and 57: Commissioning, Startup, Operation,

- Page 58 and 59: Commissioning, Startup, Operation,

- Page 60 and 61: Commissioning, Startup, Operation,

- Page 62 and 63: Commissioning, Startup, Operation,

- Page 64 and 65: Commissioning, Startup, Operation,

- Page 66 and 67: MaintenanceMaintenanceMaintenance s

- Page 68 and 69: Maintenance (Continued)Regrease the

- Page 70 and 71: Maintenance (Continued)Packed stuff

- Page 72 and 73: Maintenance (Continued)1. Is your b

- Page 74 and 75: Maintenance (Continued)Clean surfac

- Page 76 and 77: Maintenance (Continued)5. Remove th

- Page 78 and 79: Maintenance (Continued)3. Remove th

- Page 80 and 81: Maintenance (Continued)134236A370D4

- Page 82 and 83: Maintenance (Continued)253B168A4961

- Page 84 and 85: Maintenance (Continued)2. Loosen th

- Page 86 and 87: Maintenance (Continued)Surface insp

- Page 88 and 89: Maintenance (Continued)444Figure 24

- Page 90 and 91: Maintenance (Continued)Bearing fits

- Page 92 and 93: Maintenance (Continued)168361A12238

- Page 94 and 95: Maintenance (Continued)372T 113A 40

- Page 96 and 97: Maintenance (Continued)a) Coat the

- Page 98 and 99: Maintenance (Continued)13411. Prepa

- Page 100 and 101: Maintenance (Continued)4. Check the

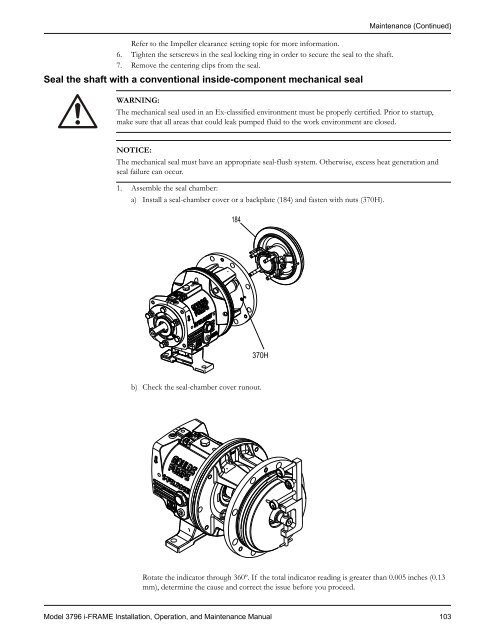

- Page 102 and 103: Maintenance (Continued)333AINPRO la

- Page 106 and 107: Maintenance (Continued)c) Install t

- Page 108 and 109: Maintenance (Continued)126412A101In

- Page 110 and 111: Maintenance (Continued).030101For m

- Page 112 and 113: Maintenance (Continued)100351418100

- Page 114 and 115: Maintenance (Continued)Table 18: Ma

- Page 116 and 117: Maintenance (Continued)Table 22: Lu

- Page 118 and 119: TroubleshootingTroubleshootingOpera

- Page 120 and 121: Troubleshooting (Continued)i-ALERT

- Page 122 and 123: Parts Listings and Cross-Sectional

- Page 124 and 125: Parts Listings and Cross-Sectional

- Page 126 and 127: Parts Listings and Cross-Sectional

- Page 128 and 129: Parts Listings and Cross-Sectional

- Page 130 and 131: Parts Listings and Cross-Sectional

- Page 132: Other Relevant Documentation or Man