Installation Operation and Maintenance Manual

Installation Operation and Maintenance Manual (IOM) - Goulds Pumps

Installation Operation and Maintenance Manual (IOM) - Goulds Pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

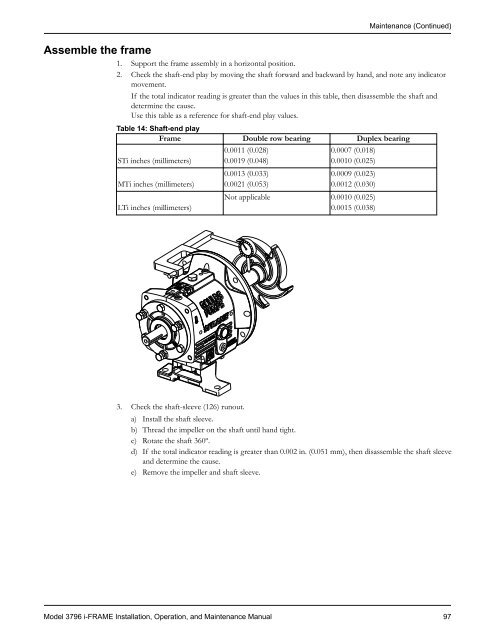

<strong>Maintenance</strong> (Continued)Assemble the frame1. Support the frame assembly in a horizontal position.2. Check the shaft-end play by moving the shaft forward <strong>and</strong> backward by h<strong>and</strong>, <strong>and</strong> note any indicatormovement.If the total indicator reading is greater than the values in this table, then disassemble the shaft <strong>and</strong>determine the cause.Use this table as a reference for shaft-end play values.Table 14: Shaft-end playFrame Double row bearing Duplex bearingSTi inches (millimeters)MTi inches (millimeters)LTi inches (millimeters)0.0011 (0.028)0.0019 (0.048)0.0013 (0.033)0.0021 (0.053)0.0007 (0.018)0.0010 (0.025)0.0009 (0.023)0.0012 (0.030)Not applicable 0.0010 (0.025)0.0015 (0.038)3. Check the shaft-sleeve (126) runout.a) Install the shaft sleeve.b) Thread the impeller on the shaft until h<strong>and</strong> tight.c) Rotate the shaft 360º.d) If the total indicator reading is greater than 0.002 in. (0.051 mm), then disassemble the shaft sleeve<strong>and</strong> determine the cause.e) Remove the impeller <strong>and</strong> shaft sleeve.Model 3796 i-FRAME <strong>Installation</strong>, <strong>Operation</strong>, <strong>and</strong> <strong>Maintenance</strong> <strong>Manual</strong> 97