A1A - EIL Tender portal

A1A - EIL Tender portal

A1A - EIL Tender portal

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

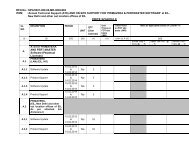

JOB SPECIFICATION<br />

FOR SURFACE PREPARATION<br />

AND PROTECTIVE COATING<br />

JOB SPECIFICATION No.<br />

A307-000-06-42-PLS-01<br />

Rev.0<br />

PAGE 19 OF 49<br />

PAINT MATERIALS<br />

TABLE No. 6.4 FINISH PAINTS<br />

Sl.<br />

No<br />

DESCRIPTION F-14 F-15 F-16 F-17<br />

Ambient temperature<br />

1 Technical name<br />

curing Poly Siloxane<br />

Two-component<br />

Two component<br />

coating/High build<br />

Epoxy phenolic<br />

solvent free type<br />

cold applied inorganic<br />

coating cured with<br />

high build epoxy<br />

copolymer based<br />

Polyamine cured Polyamine adduct<br />

phenolic/novalac<br />

aluminium coating<br />

coal tar epoxy hardner system<br />

epoxy phenolic<br />

suitable for under<br />

(primer +<br />

coating cured with<br />

insulation coating of<br />

intermediate coat<br />

Polyamine adduct<br />

CS and SS piping for<br />

+ finish paint)<br />

hardner system<br />

high temperature<br />

service.<br />

2 Type & composition<br />

Two pack ambient<br />

Two component<br />

Specially<br />

temperature curing Amercoat 738 from solvent free type<br />

formulated<br />

epoxy phenolic PPG Protective & high build epoxy<br />

polyamine cured<br />

coating system Marine Coatings or phenolic/novalac<br />

coal tar epoxy<br />

suitable for Intertherm 751 CSA of epoxy phenolic<br />

suitable for<br />

application under International (Akzo coating cured with<br />

application under<br />

insulation of Nobel). Note: 6 Polyamine adduct<br />

insulation<br />

CS/SS piping<br />

hardner system<br />

3 Volume Solids % 70±3 70±3 60±2 98-100<br />

4<br />

DFT (Dry Film<br />

thickness) per coat in 100-125 75-100 75-100 125- 150<br />

microns<br />

5<br />

Theoritical covering<br />

capacity in M 2 /coat/ 5-8 4-5 7.0- 9.0 6.5 - 8<br />

litre<br />

6<br />

Weight per liter in<br />

kgs/litre (mix paint)<br />

1.45±0.03 1.65±0.03 1.3 1.7<br />

7<br />

Touch dry at 30 o C<br />

(maximum)<br />

4 hrs 3 hrs 1 hr 2 hrs<br />

8<br />

Hard dry at 30 o C<br />

(maximum)<br />

Full cure 30 o C (for<br />

immersion /high<br />

temp. service)<br />

24 hrs<br />

168 hrs (7 days)<br />

24 hrs<br />

168 hrs (7 days)<br />

16 hrs<br />

-<br />

24 hrs<br />

168 hrs (7 days)<br />

9<br />

10<br />

11<br />

Over-coating interval<br />

Pot life at 30 o C for<br />

two component<br />

paints<br />

Temperature<br />

Resistance<br />

Min. 6 hrs<br />

Max.5 days<br />

Min. 36 hrs<br />

Max.21 days<br />

Min.16 hrs<br />

Max. Not applicable<br />

Min. 16 hrs<br />

Max.21 days<br />

4 hrs 4-6 hrs 1 hr 1 hr<br />

-45 o C to 125 o C<br />

under insulation<br />

And immersion<br />

-45 o C to 150 o C<br />

under insulation &<br />

immersion<br />

(Note: 5)<br />

a) upto 400 °C for C.<br />

Steel & S. Steel for<br />

Intertherm 751 CSA<br />

b) upto 480 °C for C.<br />

Steel & upto 600 °C<br />

for S. Steel for<br />

Amercoat 738<br />

-45 o C to 150 o C for<br />

immersion service<br />

Format No. 8-00-0001-F1 Rev. 0<br />

Copyright <strong>EIL</strong> – All rights reserved<br />

Page 258 of 291