A1A - EIL Tender portal

A1A - EIL Tender portal

A1A - EIL Tender portal

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

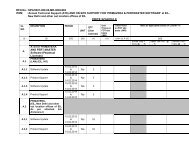

JOB SPECIFICATION<br />

FOR SURFACE PREPARATION<br />

AND PROTECTIVE COATING<br />

JOB SPECIFICATION No.<br />

A307-000-06-42-PLS-01<br />

Rev.0<br />

PAGE 48 OF 49<br />

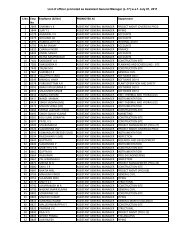

HBTI, Kanpur<br />

DMSRDE, Kanpur<br />

BIS Laboratories<br />

UICT, Matunga, Mumbai<br />

RITES, Kolkata<br />

PDIL, Sindri<br />

NTH, Kolkata<br />

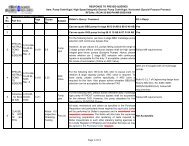

Contractor shall furnish to <strong>EIL</strong> for approval/ acceptance of all necessary<br />

documents/information including test certificates to prove that the paint manufacturers, from<br />

whom he intends to procure paint products, meet the various requirements for fulfilling the<br />

pre-qualification criteria as given under section 25.1 above. The paint manufacturer shall be<br />

qualified and approved for supply after review/assessment of the submission made by the<br />

contractor.<br />

25.2 Information to be furnished during delivery of coating system:<br />

Contractor along with delivery of paint material has to furnish following information from<br />

paint manufacturer to <strong>EIL</strong> for acceptance/approval of products.<br />

a) Batch test certificates (Batch Testing)<br />

Along with delivery to site of the paint products from pre-qualified coating manufacturer.<br />

Contractor has to produce test certificate from paint manufacturer for each batch and for<br />

each category of product for the following test items. Test to be witnessed & certified<br />

by third party inspection agency. All test results must mention clearly the batch no. and<br />

category of product tested. Tests to be conducted for following properties:<br />

- Infrared scan for Part A and B, each component<br />

- Specific Gravity<br />

- % solids by weight (% zinc content in case of inorganic or organic zinc primer)<br />

b) Product information sheet/ technical data sheet for each category of product.<br />

26.0 METHOD OF SAMPLING & DISPATCH FOR LABORATORY TESTING<br />

(Pre-Qualification tests (sec. 25.1), Batch testing (sec. 25.2) and Inspection testing (sec.<br />

22.0))<br />

26.1 Samples of coating materials should be submitted to the Govt. laboratory in sealed containers<br />

with batch no. and test certificate on regular format of manufacturer’s testing laboratory. The<br />

sampling shall be certified and sealed by a certifying agency.<br />

26.2 All test panels should be prepared by Govt. testing agency coloured photographs of test<br />

panels should be taken before and after the test and should be enclosed along with test report.<br />

Sample batch no. and manufacturer’s test certificate should be enclosed along with the<br />

report. Test report must contain details of observation and rusting if any, as per the testing<br />

code.<br />

26.3 Manufacturers should intimate the company, details of sample submitted for testing, name of<br />

Govt. testing agency, date, contact personnel of the govt. testing agency. At the end of the<br />

test the manufacturer should submit the test reports to the company for approval.<br />

Format No. 8-00-0001-F1 Rev. 0<br />

Copyright <strong>EIL</strong> – All rights reserved<br />

Page 287 of 291