A1A - EIL Tender portal

A1A - EIL Tender portal

A1A - EIL Tender portal

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

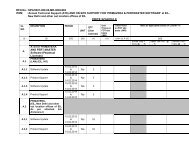

JOB SPECIFICATION<br />

FOR SURFACE PREPARATION<br />

AND PROTECTIVE COATING<br />

JOB SPECIFICATION No.<br />

A307-000-06-42-PLS-01<br />

Rev.0<br />

PAGE 31 OF 49<br />

13.6<br />

AGGRESSIVE SOLVENTS LIKE HEXANE, HEXENE, BENZENE, XYLENE AND TOLUENE<br />

All internal surfaces, accessories and roof structures of Cone and Dome roof tanks<br />

13.6.<br />

1<br />

-14 to 65 SSPC-SP-10<br />

1 coat of F-9 @ 75µ<br />

DFT/ coat<br />

--- 75 -<br />

13.7<br />

ETHYLENE GLYCOL (EG) TANKS<br />

Internal shell-full height, bottom plate, underside of roof and all accessories<br />

3 coats of vinyl<br />

chloride co-polymer<br />

13.7.<br />

All SSPC-SP-10 None<br />

AMERCOAT 23 @<br />

1<br />

75µ /Coat;<br />

225 -<br />

(3x75=225)<br />

13.8 Inside pontoon and inside of double deck of all floating roofs<br />

13.8.<br />

1 coat of F-8 @ 100µ 1 coat of F-8 @ 100µ<br />

-14 to 80 SSPC-SP-3<br />

1<br />

DFT/coat<br />

DFT/coat<br />

200 -<br />

13.9<br />

WET SLOPS, AMINE solutions, SOUR WATER , WATER DRAW OFF<br />

All internal surfaces, accessories and roof structures of Cone and Dome roof tanks<br />

1 coat of F-15<br />

intermediate coat @<br />

13.9.<br />

1 coat of F-15 primer @ 80µ DFT/coat + 1 coat<br />

-14 to 90 SSPC-SP-10<br />

1<br />

80µ DFT/ coat of F-15 finish coat @<br />

240 -<br />

80µ DFT/ coat;<br />

(80+80=160)<br />

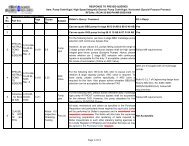

VACUUM RESIDUE, FUEL OIL , DRY SLOP, BITUMEN AND OTHER HIGH TEMPERATURE<br />

HYDROCARBON LIQUIDS<br />

13.10 Underside of floating roof, internal surface of cone roof, bottom plate, inside of bare shell – including<br />

wetted and non wetted surfaces, oil side surfaces of deck plates, oil side surfaces of pontoons, roof<br />

13.10<br />

.1<br />

13.11<br />

13.11<br />

.1<br />

structures, structural steel and ladders<br />

Up to 150 o C<br />

SSPC-SP-10<br />

1 coat of F-17 primer<br />

@ 125µ DFT/ coat<br />

1 coat of F-17<br />

intermediate coat @<br />

125µ DFT/coat + 1 coat<br />

of F-17 finish coat<br />

@125µ DFT/ coat;<br />

(125+125=250)<br />

ALKALIS UP TO 50 % CONCENTRATION<br />

All internal surfaces, accessories and roof structures of Cone and Dome roof tanks<br />

2 Coats of F-6 A @<br />

Up to 60 o 1 coat of F-15 primer @<br />

C SSPC-SP-10<br />

100µ DFT/coat;<br />

80µ DFT/ coat<br />

(2x100=200)<br />

375 Note:3<br />

280-100 -<br />

NOTES<br />

1. All paint coating application including primer shall be carried out after erection and completion<br />

of all welding work at site.<br />

2. F-6A should be suitable and resistant for immersion service for the respective Hydrocarbons.<br />

3. This system can be used where maximum operating temperature is below 150 o C and design<br />

temperature is upto 200 o C. Cases of operating temperature > 150 o C are not covered in this spec,<br />

such cases shall be covered in the job specifications.<br />

4 F-6 A shall be suitable for drinking water service and should have competent authority<br />

certification.<br />

Format No. 8-00-0001-F1 Rev. 0<br />

Copyright <strong>EIL</strong> – All rights reserved<br />

Page 270 of 291