A1A - EIL Tender portal

A1A - EIL Tender portal

A1A - EIL Tender portal

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

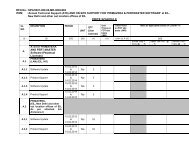

JOB SPECIFICATION<br />

FOR SURFACE PREPARATION<br />

AND PROTECTIVE COATING<br />

JOB SPECIFICATION No.<br />

A307-000-06-42-PLS-01<br />

Rev.0<br />

PAGE 27 OF 49<br />

TABLE 11.0<br />

COATING SYSTEM FOR EFFLUENT TREATMENT PLANT (ETP)<br />

Sl.<br />

No.<br />

11.1<br />

11.2<br />

11.3<br />

11.4<br />

Design Temp.<br />

in o C<br />

Surface Preparation<br />

Coating System<br />

Primer<br />

Finish Coat<br />

Total<br />

DFT in<br />

Microns<br />

(min.)<br />

Remarks<br />

For External Surfaces of C.S./M.S. items: Screens, Walk way bridges, Baffles, Dual media filters,<br />

Vertical pumps, piping in treated effluent sump, bio sludge pump, Screw pump and pump house, CS<br />

tanks, sumps and vessels.<br />

-14 to 80 SSPS-SP-10<br />

1 coat of F-9<br />

@ 65-75µ<br />

DFT/coat<br />

2 coats of<br />

F-6A @100µ<br />

DFT/coat + 1<br />

coat of F-2 @<br />

40µ<br />

DFT/coat;<br />

(2x100+40=2<br />

40)<br />

305-315 -<br />

For Internal Surfaces of CS/MS Items: Bio-sludge sump, Filter feed sump, Process sump, Sanitary<br />

sump, Transfer sump, Sludge, Slop oil tank, scrapping mechanism in Clarifier<br />

3 coats of<br />

1 coat of F-9<br />

F-6A @100µ<br />

-14 to 80 SSPS-SP-10 @ 65-75µ<br />

365-375 Note:1<br />

DFT/coat<br />

DFT/coat.<br />

(3x100=300)<br />

All R.C.C./concrete surfaces exposed to effluent water / liquid such as tanks, structures, drains etc.<br />

in Process sump, TPI separator (Process and Oil), Aeration Tank and Transfer sump etc.<br />

Epoxy screed<br />

lining shall be<br />

Blast cleaning to SSPC-SP<br />

applied as per<br />

guide lines and Acid<br />

specific<br />

-14 to 80 etching with 10-15% HCl Epoxy Screed lining 3mm<br />

manufacturer<br />

acid followed by thorough<br />

and Engineerin-Charge<br />

water washing.<br />

instructions<br />

C.S/M.S Dual media filters (Internal), Chemical dosing tanks(internal) such as Di-Ammonium<br />

Phosphate (DAP) and Urea<br />

Natural<br />

Rubber lining<br />

shall be<br />

Up to 60 SSPC-SP-10<br />

Natural Rubber Lining<br />

(As per IS 4682, Part 1) 4.5mm<br />

applied as per<br />

specific<br />

manufacturer<br />

and Engineerin-Charge<br />

instructions<br />

NOTES<br />

1. The paint /coating manufacturers shall provide their Quality control test certificate of coating<br />

materials (F-6A) for immersion service of the exposed effluent given in 11.2.<br />

Format No. 8-00-0001-F1 Rev. 0<br />

Copyright <strong>EIL</strong> – All rights reserved<br />

Page 266 of 291