Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>ICAM</strong> <strong>Virtual</strong> <strong>Machine</strong> ® Version 19.0 Using <strong>Virtual</strong> <strong>Machine</strong> Models with CeRun and Gener<br />

Monitoring <strong>Virtual</strong> <strong>Machine</strong>’s Results<br />

2.10.5 Part / Stock Comparison<br />

Comparison between the design part and the inprocess<br />

stock is only available with a MRS (Material<br />

Removal Simulation) license available and<br />

enabled via the SIM button on the GENER and CERUN launch panels. The MRS license provides<br />

the added functionality to compute the effect of the cutting process of the tool on the rough<br />

stock. The resultant shape is called the “in-process stock”.<br />

The left-most of the circled buttons above toggles the display of the in-process stock. The two<br />

buttons to its immediate right toggle the display of Boolean Overcut (gouge) and Boolean<br />

Undercut (excess) material. The gouge and excess calculations are done using an exact comparison<br />

between in-process stock and its associated part. These associations must first be setup using<br />

the “Associated Part” setting in the Simulation»Stock (Ctrl Alt S shortcut) dialog (on page 18).<br />

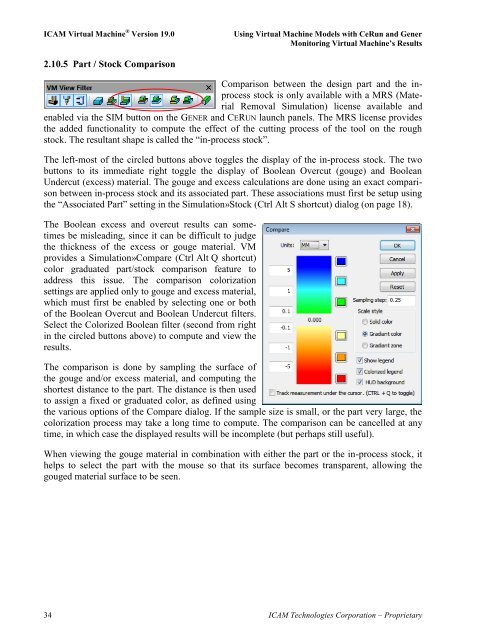

The Boolean excess and overcut results can sometimes<br />

be misleading, since it can be difficult to judge<br />

the thickness of the excess or gouge material. VM<br />

provides a Simulation»Compare (Ctrl Alt Q shortcut)<br />

color graduated part/stock comparison feature to<br />

address this issue. The comparison colorization<br />

settings are applied only to gouge and excess material,<br />

which must first be enabled by selecting one or both<br />

of the Boolean Overcut and Boolean Undercut filters.<br />

Select the Colorized Boolean filter (second from right<br />

in the circled buttons above) to compute and view the<br />

results.<br />

The comparison is done by sampling the surface of<br />

the gouge and/or excess material, and computing the<br />

shortest distance to the part. The distance is then used<br />

to assign a fixed or graduated color, as defined using<br />

the various options of the Compare dialog. If the sample size is small, or the part very large, the<br />

colorization process may take a long time to compute. The comparison can be cancelled at any<br />

time, in which case the displayed results will be incomplete (but perhaps still useful).<br />

When viewing the gouge material in combination with either the part or the in-process stock, it<br />

helps to select the part with the mouse so that its surface becomes transparent, allowing the<br />

gouged material surface to be seen.<br />

34 <strong>ICAM</strong> Technologies Corporation – Proprietary