IJUP08 - Universidade do Porto

IJUP08 - Universidade do Porto

IJUP08 - Universidade do Porto

- TAGS

- universidade

- porto

- ijup.up.pt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Wet Peroxide Oxidation and Wet Oxidation of Nitrophenols in<br />

Aqueous Streams<br />

S. Martins 1,2 , A. Ribeiro 2 , A.M.T. Silva 1 , P. Araújo 2 , J.L. Figueire<strong>do</strong> 1 , and J.L. Faria 1<br />

1 Laboratório de Catálise e Materiais, Departamento de Engenharia Química, Faculdade de<br />

Engenharia da <strong>Universidade</strong> <strong>do</strong> <strong>Porto</strong>, Rua Dr. Roberto Frias s/n, 4200-465 <strong>Porto</strong>, Portugal<br />

2 CUF – Químicos de Portugal, S.A., Quinta da Indústria, 3860-680 Estarreja, Portugal<br />

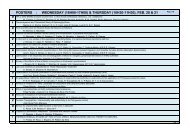

The treatment of nitrophenols, typically found in the effluents from the process of<br />

nitrobenzene synthesis, was carried out by wet oxidation (WO) and wet peroxide oxidation<br />

(WPO). These processes are based in the principles of wet air oxidation, an efficient<br />

process for treatment of high strength effluents which cannot be treated by conventional<br />

methods [1]. In this process the organics are oxidized in the liquid phase at temperatures<br />

around 300ºC and pressures of 5 to 200 bar, in presence of an oxygen-containing agent<br />

(usually air). This process has low operating costs and minimal air pollution discharges,<br />

the main limitations being the safety implications<br />

associated with a system operating at such<br />

conditions [2]. Under the usual conditions, the<br />

organic compounds are mainly oxidized into<br />

carbon dioxide and water. Our previous studies<br />

show that this process is efficient above 200ºC<br />

and 7.0 bar of O2 in the degradation of low<br />

dinitrophenol (DNP) and trinitrophenol (TNP)<br />

concentrations (below 0.4 g/L) [3]. However,<br />

these operating conditions are quite severe for<br />

industrial scale-up and higher concentrations of<br />

Figure 1 – Evolution of the C/C0 ratio to<br />

DNP and TNP.<br />

nitrophenols (above 10 g/L) are usually found in real effluents. Therefore, the use<br />

hydrogen peroxide (H2O2) as additional oxidizing agent was investigated in this work (wet<br />

peroxide oxidation process) aiming to obtain a high efficiency at lower temperatures and<br />

pressures. In a wide range of concentrations of nitrophenols the use of mild conditions for<br />

temperature and O2 pressure (without H2O2) resulted in conversions up to 99.3 and 98.5%<br />

for DNP and TNP, respectively (Fig.1). An initial period of 30 min was necessary to<br />

achieve the working temperature. At the same temperature, with an oxygen pressure of 0.8<br />

bar with the higher peroxide concentration used, a complete destruction of nitrophenols<br />

was observed. Reducing temperature, keeping the oxygen pressure, but reducing peroxide<br />

concentration to 56.1 g/L, resulted in maximum conversions of 92.1 and 99.8% for DNP<br />

and TNP, respectively. Global TOC removal efficiencies ranged from 57 to 97%.<br />

Therefore, the WPO is strongly recommended in the degradation of nitrophenols.<br />

References:<br />

[1] – Mishra, V.S, Mahajani, V.V. and Joshi J.B. (1995) Wet Air Oxidation, Industrial &<br />

Engineering Chemistry Resaerch 34(1), 2-48.<br />

[2] – Kolaczkowski, S. T., P. Plucinski, et al. (1999). Wet air oxidation: a review of process<br />

technologies and aspects in reactor design, Chemical Engineering Journal 73(2), 143-160.<br />

[3] – Apolinário, Â .C., Silva, A.M.T., Macha<strong>do</strong>, B.F., Gomes, H.T., Araújo, P.P., Figueire<strong>do</strong>, J.L.,<br />

Faria, J.L. (2007), Wet air oxidation of nitro-aromatic compounds: reactivity on single- and multi<br />

component systems and surface chemistry studies with a carbon xerogel, Applied Catalysis B,<br />

Environmental, (in press, <strong>do</strong>i:10.1016/j.apcatb.2007.12.018).<br />

C/C0<br />

1,6<br />

1,2<br />

0,8<br />

0,4<br />

0<br />

DNP<br />

TNP<br />

-30 -15 0 15 30 45 60 75 90 105 120<br />

t (min)<br />

159