IJUP08 - Universidade do Porto

IJUP08 - Universidade do Porto

IJUP08 - Universidade do Porto

- TAGS

- universidade

- porto

- ijup.up.pt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

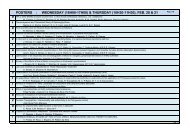

Incorporation of organics/inorganics nanocomposites in coatings<br />

of high environmental and mechanical resistance<br />

J. Pimenta 1 , C. Carneiro 2 , A. Mendes 3 , J. Moniz 4 , F. Oliveira 2 , F. Magalhães 3<br />

1 Rede de Competência em Polímeros, <strong>Porto</strong>, Portugal.<br />

2 CIN – Corporação Industrial <strong>do</strong> Norte, S.A., Maia, Portugal<br />

3 Department of Chemical Engineering, Faculty of Engineering, University of <strong>Porto</strong>, Portugal.<br />

4 Resiquímica – Resinas Químicas, S.A, Lisboa, Portugal<br />

Inorganic fillers (metal oxides included) have been traditionally used in organic coatings,<br />

conferring improved mechanical and physicochemical properties. In recent years, the<br />

ability to produce inorganic fillers in nano-sized dispersible dimensions has attracted new<br />

attention over an otherwise well established field. Indeed, the performance of the<br />

inorganic-organic composites is optimized when the fillers are present in dimensions<br />

below 100 nm (nano-size). However, this is only effective if the materials are uniformly<br />

dispersed throughout the final coating film. When dealing with water based coatings,<br />

obtained from polymeric emulsions, it is important to ensure that the inorganic<br />

nanoparticles are well dispersed, either through encapsulation within the polymer particles<br />

or dispersion in the aqueous phase. The first situation may be the most desirable, since it<br />

should lead to a more uniform particle distribution in the coalesced film.<br />

One of the main motivations for this research is the development of enhanced intumescent<br />

paints (which expand when heated, creating a barrier to heat transmission and therefore<br />

protecting the substract from the high temperatures occurring during a fire [1]).<br />

Our work has been focused on incorporating nano-sized silica (SiO2) particles in vinylic<br />

emulsions. The initial approach consisted is pre-dispersing powdered nanosilica in the<br />

colloidal solution that is the starting point for the emulsion polymerization reaction. Two<br />

types of nanosilica were selected: Sil-1 (with surface treatment) and Sil-2 (without surface<br />

treatment).<br />

For Sil-1, some methods of dispersion have been studied in order to avoid suprananometric<br />

agglomeration in the aqueous phase: Cowles agitator, ultrasound and bead milling. The<br />

later gave the best results. After polymerization of the vinylic monomers, TEM microscopy<br />

indicated that there was silica present in the surrounding aqueous phase, probably<br />

stabilized by the colloid, and encapsulation by the polymer could not be confirmed due to<br />

the opacity of the polymeric particles.<br />

Concerning Sil-2, TEM analysis indicated that these<br />

nano particles tend to attach to the surface of the<br />

polymeric particles and encapsulation is improbable in<br />

this case (Fig. 1). Current work is dealing with<br />

promoting the encapsulation of Sil-1 in the polymer, by<br />

developing a colloid-free formulation, and the<br />

encapsulation of Sil-2, by using a comonomer with<br />

affinity to its surface.<br />

References:<br />

[1] – Nogueira J. L. (2006), Protecção passiva contra o fogo.<br />

Figure 1 – polymer emulsion<br />

particle surrounded by Sil-2<br />

74