IJUP08 - Universidade do Porto

IJUP08 - Universidade do Porto

IJUP08 - Universidade do Porto

- TAGS

- universidade

- porto

- ijup.up.pt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

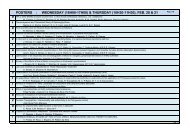

Synthesis of vesiculated polyester particles and its incorporation<br />

in paints<br />

A. Dias 1, A. Mendes 2, F. Oliveira3, J. Moniz4 and F.D. Magalhães2<br />

1 Rede de Competência em Polímeros, <strong>Porto</strong>, Portugal.<br />

2 Department of Chemical Engineering, Faculty of Engineering, University of <strong>Porto</strong>, Portugal.<br />

3 CIN -Corporação Industrial <strong>do</strong> Norte, S.A., Maia, Portugal.<br />

4 Resiquímica -Resinas Químicas, S.A., Lisboa, Portugal.<br />

Titanium dioxide is a white pigment which confers to paints high whitening index and<br />

opacity due to its capability of scattering the light and low absorption power. However,<br />

titanium dioxide is currently one of the most expensive raw materials used in a paint<br />

formulation, so it is very important for the paint industry to reduce its quantity in paints.<br />

Vesiculated particles (VP) consist of an aqueous emulsion of reticulated polyester particles<br />

that incorporate numerous water-filled spaces [1]. When a film made with these particles is<br />

dried, the water contained in the core evaporates creating air voids (Figure 1), which<br />

scatter the light, due to the difference in refraction index between the polymer and the air<br />

<strong>do</strong>mains. This film will therefore appear white to the eye. Then, VP are suitable for the<br />

beneficial replacement of titanium dioxide present in paint formulation.<br />

The process for the production of VP begins with the formation of a first emulsion in<br />

which an aqueous phase is emulsified in a mixture of the unsaturated polyester, styrene and<br />

a base. The resulting “water-in-oil” emulsion is then itself emulsified and stabilized into an<br />

aqueous phase, at high shear. Then, a free radical polymerization is initiated at room<br />

temperature, which leads to the reticulation of polyester with styrene and the subsequent<br />

production of solid vesiculated particles. The VPs obtained by this <strong>do</strong>uble emulsion have a<br />

solid content of 13% and a mean particle diameter of 5 μm.<br />

Fig.1. Cryo-SEM image of air voids in vesiculated particles.<br />

The stability of the first emulsion was studied by adding different kinds of bases at<br />

different concentrations. It was possible to emulsify 150% of water into the polyester phase<br />

by adding triethanolamine in a 0.5 mmol/g concentration. The base must be added to the<br />

oil phase to react with the carboxylic group of the polyester to form at the waterpolymer<br />

interface polyester salts, which act as true emulsifying agents [2]. This emulsion can be<br />

further optimized in the presence of a surfactant.<br />

The stability of the second emulsion is also being studied, in terms of the optimal<br />

stabilizers concentration. In addition, the conditions for the final reticulation process are<br />

also being optimized.<br />

References:<br />

[1] Engelbrecht, J. et al. (2006), Vesiculated polymer particles, US patent 2006/0111474.<br />

[2] Horie, K., Mita.I. and Kambe H. (1967), Copolimerization of unsaturated polyester with styrene in<br />

inverted emulsion, Journal of applied polymer science, 11, pp. 57-71.<br />

185