Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

Collets<br />

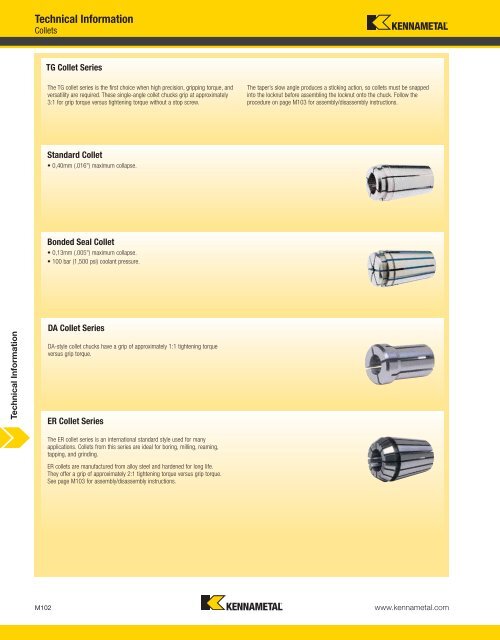

TG Collet Series<br />

The TG collet series is the first choice when high precision, gripping torque, and<br />

versatility are required. These single-angle collet chucks grip at approximately<br />

3:1 for grip torque versus tightening torque without a stop screw.<br />

Standard Collet<br />

• 0,40mm (.016") maximum collapse.<br />

Bonded Seal Collet<br />

• 0,13mm (.005") maximum collapse.<br />

• 100 bar (1,500 psi) coolant pressure.<br />

DA Collet Series<br />

DA-style collet chucks have a grip of approximately 1:1 tightening torque<br />

versus grip torque.<br />

ER Collet Series<br />

The ER collet series is an international standard style used for many<br />

applications. Collets from this series are ideal for boring, milling, reaming,<br />

tapping, and grinding.<br />

ER collets are manufactured from alloy steel and hardened for long life.<br />

They offer a grip of approximately 2:1 tightening torque versus grip torque.<br />

See page M103 for assembly/disassembly instructions.<br />

The taper’s slow angle produces a sticking action, so collets must be snapped<br />

into the locknut before assembling the locknut onto the chuck. Follow the<br />

procedure on page M103 for assembly/disassembly instructions.<br />

M102 www.kennametal.com