Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

Collet Chuck Styles<br />

Collet Chuck Styles<br />

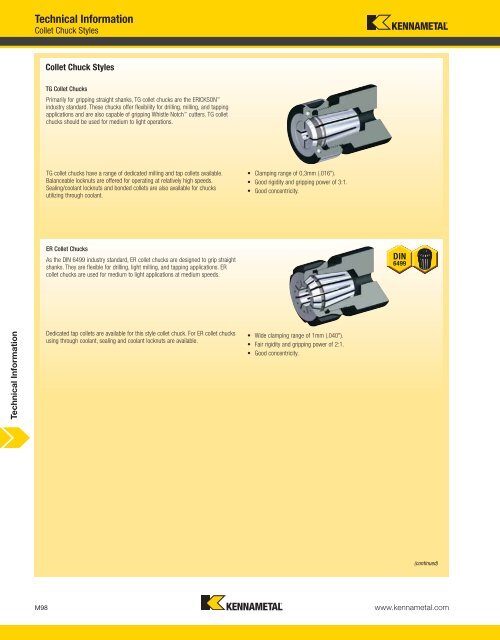

TG Collet Chucks<br />

Primarily for gripping straight shanks, TG collet chucks are the ERICKSON <br />

industry standard. These chucks offer flexibility for drilling, milling, and tapping<br />

applications and are also capable of gripping Whistle Notch cutters. TG collet<br />

chucks should be used for medium to light operations.<br />

TG collet chucks have a range of dedicated milling and tap collets available.<br />

Balanceable locknuts are offered for operating at relatively high speeds.<br />

Sealing/coolant locknuts and bonded collets are also available for chucks<br />

utilizing through coolant.<br />

ER Collet Chucks<br />

As the DIN 6499 industry standard, ER collet chucks are designed to grip straight<br />

shanks. They are flexible for drilling, light milling, and tapping applications. ER<br />

collet chucks are used for medium to light applications at medium speeds.<br />

Dedicated tap collets are available for this style collet chuck. For ER collet chucks<br />

using through coolant, sealing and coolant locknuts are available.<br />

• Clamping range of 0,3mm (.016").<br />

• Good rigidity and gripping power of 3:1.<br />

• Good concentricity.<br />

• Wide clamping range of 1mm (.040").<br />

• Fair rigidity and gripping power of 2:1.<br />

• Good concentricity.<br />

(continued)<br />

M98 www.kennametal.com