You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Balancing (continued)<br />

The permissible residual unbalance can be calculated by the following equation:<br />

F = U x (n/9,549) 2 (Newtons)<br />

Where:<br />

In this particular case, the unbalanced induced force would be<br />

F = 1 x (25,000/9,549)2 = 6,9 N. The cutting forces generated<br />

are likely to be orders of magnitude greater than that.<br />

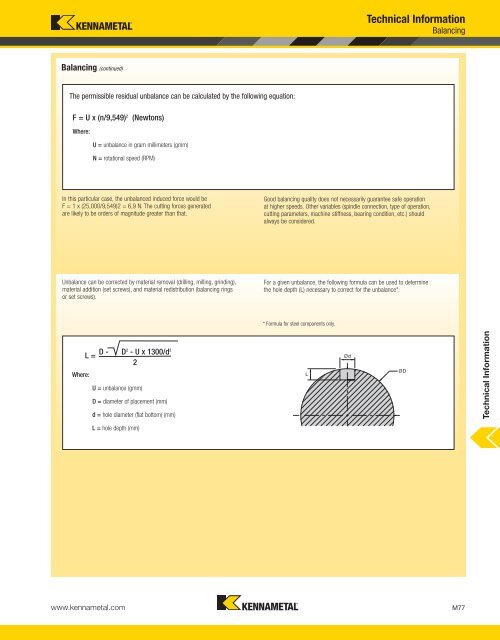

Unbalance can be corrected by material removal (drilling, milling, grinding),<br />

material addition (set screws), and material redistribution (balancing rings<br />

or set screws).<br />

Where:<br />

www.kennametal.com<br />

U = unbalance in gram millimeters (gmm)<br />

N = rotational speed (RPM)<br />

L = D - D2 - U x 1300/d 2<br />

2<br />

U = unbalance (gmm)<br />

D = diameter of placement (mm)<br />

d = hole diameter (flat bottom) (mm)<br />

L = hole depth (mm)<br />

<strong>Technical</strong> <strong>Information</strong><br />

Balancing<br />

Good balancing quality does not necessarily guarantee safe operation<br />

at higher speeds. Other variables (spindle connection, type of operation,<br />

cutting parameters, machine stiffness, bearing condition, etc.) should<br />

always be considered.<br />

For a given unbalance, the following formula can be used to determine<br />

the hole depth (L) necessary to correct for the unbalance*:<br />

* Formula for steel components only.<br />

M77<br />

<strong>Technical</strong> <strong>Information</strong>