You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

Spindle Connection<br />

The Correct Spindle Connection<br />

and Application Guide<br />

The Spindle Connection<br />

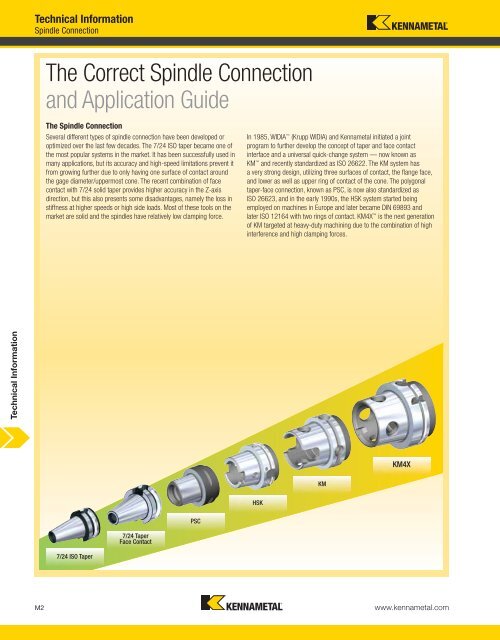

Several different types of spindle connection have been developed or<br />

optimized over the last few decades. The 7/24 ISO taper became one of<br />

the most popular systems in the market. It has been successfully used in<br />

many applications, but its accuracy and high-speed limitations prevent it<br />

from growing further due to only having one surface of contact around<br />

the gage diameter/uppermost cone. The recent combination of face<br />

contact with 7/24 solid taper provides higher accuracy in the Z-axis<br />

direction, but this also presents some disadvantages, namely the loss in<br />

stiffness at higher speeds or high side loads. Most of these tools on the<br />

market are solid and the spindles have relatively low clamping force.<br />

7/24 ISO Taper<br />

7/24 Taper<br />

Face Contact<br />

PSC<br />

In 1985, WIDIA (Krupp WIDIA) and Kennametal initiated a joint<br />

program to further develop the concept of taper and face contact<br />

interface and a universal quick-change system — now known as<br />

KM and recently standardized as ISO 26622. The KM system has<br />

a very strong design, utilizing three surfaces of contact, the flange face,<br />

and lower as well as upper ring of contact of the cone. The polygonal<br />

taper-face connection, known as PSC, is now also standardized as<br />

ISO 26623, and in the early 1990s, the HSK system started being<br />

employed on machines in Europe and later became DIN 69893 and<br />

later ISO 12164 with two rings of contact. KM4X is the next generation<br />

of KM targeted at heavy-duty machining due to the combination of high<br />

interference and high clamping forces.<br />

M2 www.kennametal.com<br />

HSK<br />

KM<br />

KM4X