Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

KM-LOC Clamping System<br />

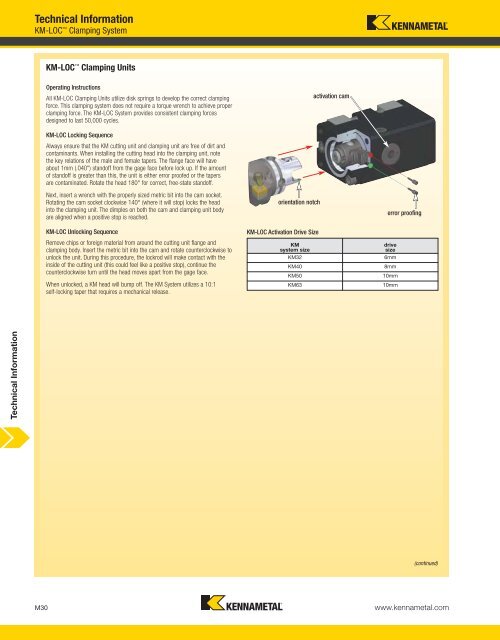

KM-LOC Clamping Units<br />

Operating Instructions<br />

All KM-LOC Clamping Units utilize disk springs to develop the correct clamping<br />

force. This clamping system does not require a torque wrench to achieve proper<br />

clamping force. The KM-LOC System provides consistent clamping forces<br />

designed to last 50,000 cycles.<br />

KM-LOC Locking Sequence<br />

Always ensure that the KM cutting unit and clamping unit are free of dirt and<br />

contaminants. When installing the cutting head into the clamping unit, note<br />

the key relations of the male and female tapers. The flange face will have<br />

about 1mm (.040") standoff from the gage face before lock up. If the amount<br />

of standoff is greater than this, the unit is either error proofed or the tapers<br />

are contaminated. Rotate the head 180° for correct, free-state standoff.<br />

Next, insert a wrench with the properly sized metric bit into the cam socket.<br />

Rotating the cam socket clockwise 140° (where it will stop) locks the head<br />

into the clamping unit. The dimples on both the cam and clamping unit body<br />

are aligned when a positive stop is reached.<br />

KM-LOC Unlocking Sequence<br />

Remove chips or foreign material from around the cutting unit flange and<br />

clamping body. Insert the metric bit into the cam and rotate counterclockwise to<br />

unlock the unit. During this procedure, the lockrod will make contact with the<br />

inside of the cutting unit (this could feel like a positive stop), continue the<br />

counterclockwise turn until the head moves apart from the gage face.<br />

When unlocked, a KM head will bump off. The KM System utilizes a 10:1<br />

self-locking taper that requires a mechanical release.<br />

orientation notch<br />

KM-LOC Activation Drive Size<br />

KM<br />

system size<br />

activation cam<br />

error proofing<br />

(continued)<br />

M30 www.kennametal.com<br />

drive<br />

size<br />

KM32 6mm<br />

KM40 8mm<br />

KM50 10mm<br />

KM63 10mm