Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

KM Manual Clamping System<br />

KM Manual Clamping Unit • Disassembly Procedures<br />

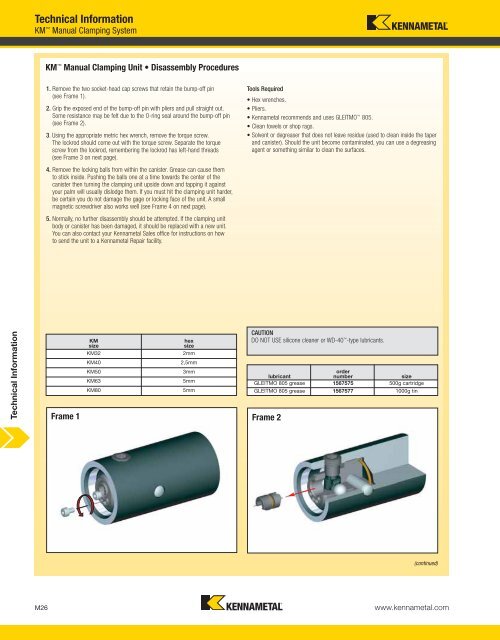

1. Remove the two socket-head cap screws that retain the bump-off pin<br />

(see Frame 1).<br />

2. Grip the exposed end of the bump-off pin with pliers and pull straight out.<br />

Some resistance may be felt due to the O-ring seal around the bump-off pin<br />

(see Frame 2).<br />

3. Using the appropriate metric hex wrench, remove the torque screw.<br />

The lockrod should come out with the torque screw. Separate the torque<br />

screw from the lockrod, remembering the lockrod has left-hand threads<br />

(see Frame 3 on next page).<br />

4. Remove the locking balls from within the canister. Grease can cause them<br />

to stick inside. Pushing the balls one at a time towards the center of the<br />

canister then turning the clamping unit upside down and tapping it against<br />

your palm will usually dislodge them. If you must hit the clamping unit harder,<br />

be certain you do not damage the gage or locking face of the unit. A small<br />

magnetic screwdriver also works well (see Frame 4 on next page).<br />

5. Normally, no further disassembly should be attempted. If the clamping unit<br />

body or canister has been damaged, it should be replaced with a new unit.<br />

You can also contact your Kennametal Sales office for instructions on how<br />

to send the unit to a Kennametal Repair facility.<br />

KM<br />

size<br />

hex<br />

size<br />

KM32 2mm<br />

KM40 2,5mm<br />

KM50 3mm<br />

KM63 5mm<br />

KM80 5mm<br />

Frame 1 Frame 2<br />

Tools Required<br />

• Hex wrenches.<br />

• Pliers.<br />

• Kennametal recommends and uses GLEITMO 805.<br />

• Clean towels or shop rags.<br />

• Solvent or degreaser that does not leave residue (used to clean inside the taper<br />

and canister). Should the unit become contaminated, you can use a degreasing<br />

agent or something similar to clean the surfaces.<br />

CAUTION<br />

DO NOT USE silicone cleaner or WD-40 -type lubricants.<br />

order<br />

lubricant<br />

number size<br />

GLEITMO 805 grease 1567575 500g cartridge<br />

GLEITMO 805 grease 1567577 1000g tin<br />

(continued)<br />

M26 www.kennametal.com