You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

Balancing<br />

Balancing (continued)<br />

permissible specific unbalance (gmm/kg)<br />

20<br />

15<br />

10<br />

5<br />

0<br />

5000 10000 15000 20000 25000 30000<br />

surface finish (Ra) vs. feed rate<br />

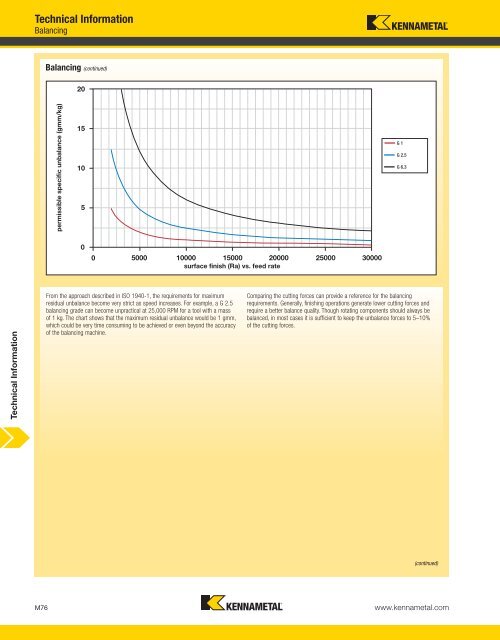

From the approach described in ISO 1940-1, the requirements for maximum<br />

residual unbalance become very strict as speed increases. For example, a G 2.5<br />

balancing grade can become unpractical at 25,000 RPM for a tool with a mass<br />

of 1 kg. The chart shows that the maximum residual unbalance would be 1 gmm,<br />

which could be very time consuming to be achieved or even beyond the accuracy<br />

of the balancing machine.<br />

Comparing the cutting forces can provide a reference for the balancing<br />

requirements. Generally, finishing operations generate lower cutting forces and<br />

require a better balance quality. Though rotating components should always be<br />

balanced, in most cases it is sufficient to keep the unbalance forces to 5–10%<br />

of the cutting forces.<br />

M76 www.kennametal.com<br />

G 1<br />

G 2.5<br />

G 6.3<br />

(continued)