You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

KM Application Data<br />

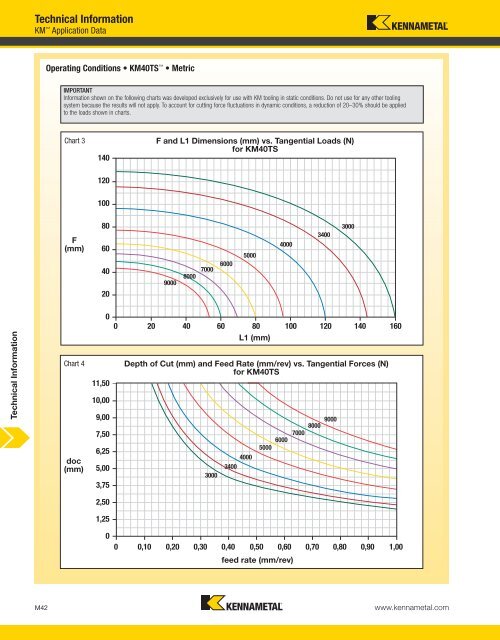

Operating Conditions • KM40TS • Metric<br />

IMPORTANT<br />

<strong>Information</strong> shown on the following charts was developed exclusively for use with KM tooling in static conditions. Do not use for any other tooling<br />

system because the results will not apply. To account for cutting force fluctuations in dynamic conditions, a reduction of 20–30% should be applied<br />

to the loads shown in charts.<br />

Chart 3<br />

F<br />

(mm)<br />

Chart 4<br />

doc<br />

(mm)<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

11,50<br />

10,00<br />

9,00<br />

7,50<br />

6,25<br />

5,00<br />

3,75<br />

2,50<br />

1,25<br />

F and L1 Dimensions (mm) vs. Tangential Loads (N)<br />

for KM40TS<br />

0<br />

0 20 40 60 80<br />

L1 (mm)<br />

100 120 140 160<br />

0<br />

9000<br />

8000<br />

7000<br />

6000<br />

Depth of Cut (mm) and Feed Rate (mm/rev) vs. Tangential Forces (N)<br />

for KM40TS<br />

3000<br />

0 0,10 0,20 0,30 0,40 0,50 0,60 0,70 0,80 0,90 1,00<br />

feed rate (mm/rev)<br />

M42 www.kennametal.com<br />

5000<br />

4000<br />

3400<br />

4000<br />

3400<br />

9000<br />

8000<br />

7000<br />

6000<br />

5000<br />

3000