Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

KM Manual Clamping System<br />

KM Manual Clamping Units<br />

KM Manual clamping units require a torque wrench to operate. Using the proper<br />

torque wrench value is critical. Tighter is not better because over tightening can<br />

cause damage.<br />

The specific operating torque of the KM manual clamping units is listed<br />

on each unit.<br />

The KM connection must be kept clean and free from nicks and burrs.<br />

KM plugs are available to ensure cleanliness when a cutting unit is not<br />

engaged in the clamping unit.<br />

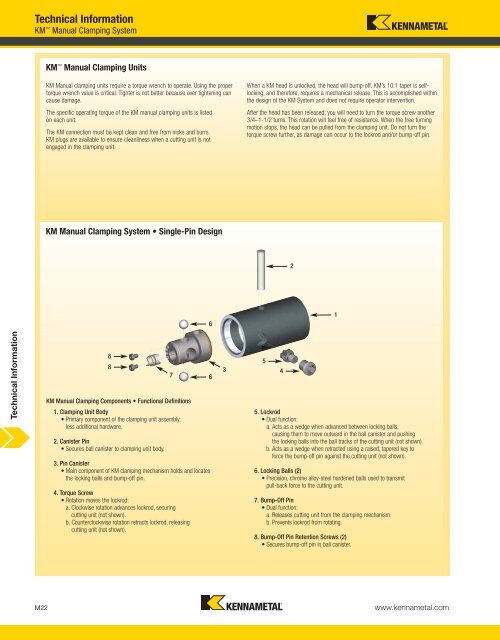

KM Manual Clamping System • Single-Pin Design<br />

8<br />

8<br />

KM Manual Clamping Components • Functional Definitions<br />

1. Clamping Unit Body<br />

• Primary component of the clamping unit assembly,<br />

less additional hardware.<br />

2. Canister Pin<br />

• Secures ball canister to clamping unit body.<br />

3. Pin Canister<br />

• Main component of KM clamping mechanism holds and locates<br />

the locking balls and bump-off pin.<br />

4. Torque Screw<br />

• Rotation moves the lockrod:<br />

a. Clockwise rotation advances lockrod, securing<br />

cutting unit (not shown).<br />

b. Counterclockwise rotation retracts lockrod, releasing<br />

cutting unit (not shown).<br />

7<br />

6<br />

6<br />

When a KM head is unlocked, the head will bump-off. KM’s 10:1 taper is selflocking,<br />

and therefore, requires a mechanical release. This is accomplished within<br />

the design of the KM System and does not require operator intervention.<br />

After the head has been released, you will need to turn the torque screw another<br />

3/4–1-1/2 turns. This rotation will feel free of resistance. When the free turning<br />

motion stops, the head can be pulled from the clamping unit. Do not turn the<br />

torque screw further, as damage can occur to the lockrod and/or bump-off pin.<br />

5<br />

3 4<br />

5. Lockrod<br />

• Dual function:<br />

a. Acts as a wedge when advanced between locking balls,<br />

causing them to move outward in the ball canister and pushing<br />

the locking balls into the ball tracks of the cutting unit (not shown).<br />

b. Acts as a wedge when retracted using a raised, tapered key to<br />

force the bump-off pin against the cutting unit (not shown).<br />

6. Locking Balls (2)<br />

• Precision, chrome alloy-steel hardened balls used to transmit<br />

pull-back force to the cutting unit.<br />

7. Bump-Off Pin<br />

• Dual function:<br />

a. Releases cutting unit from the clamping mechanism.<br />

b. Prevents lockrod from rotating.<br />

8. Bump-Off Pin Retention Screws (2)<br />

• Secures bump-off pin in ball canister.<br />

M22 www.kennametal.com<br />

2<br />

1