You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

KM Micro/KM Mini • Assembly/Disassembly Instructions (continued)<br />

Maintenance Schedule<br />

Disassemble the shanks once a month and re-apply new grease. Grease should<br />

also be applied 1 or 2 times per week to the torquw screw, nut, and both tapers<br />

(internal and external) in the release position without the need to disassemble.<br />

Before re-applying grease, shop air should be used to blow out oil coolant.<br />

If contamination of the grease is evident, then the old grease should be<br />

immediately removed and the shank cleaned. Then new grease should be<br />

re-applied acording to procedure.<br />

NOTE: Apply grease with a coarse bristle brush to prevent shedding of bristles.<br />

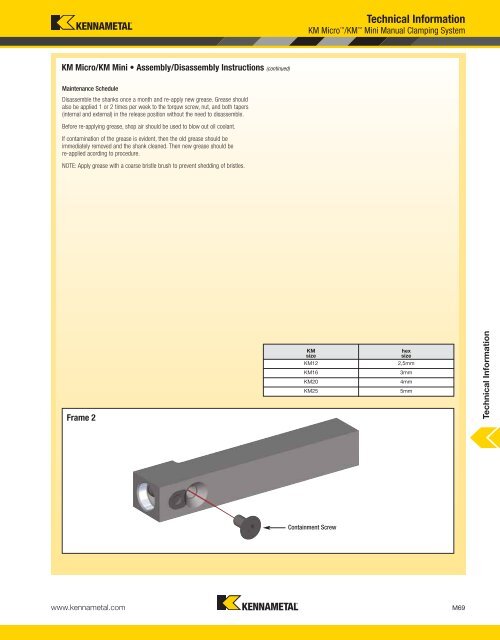

Frame 2<br />

www.kennametal.com<br />

<strong>Technical</strong> <strong>Information</strong><br />

KM Micro /KM Mini Manual Clamping System<br />

KM<br />

size<br />

Containment Screw<br />

hex<br />

size<br />

KM12 2,5mm<br />

KM16 3mm<br />

KM20 4mm<br />

KM25 5mm<br />

M69<br />

<strong>Technical</strong> <strong>Information</strong>