Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

KM ATC Configurations<br />

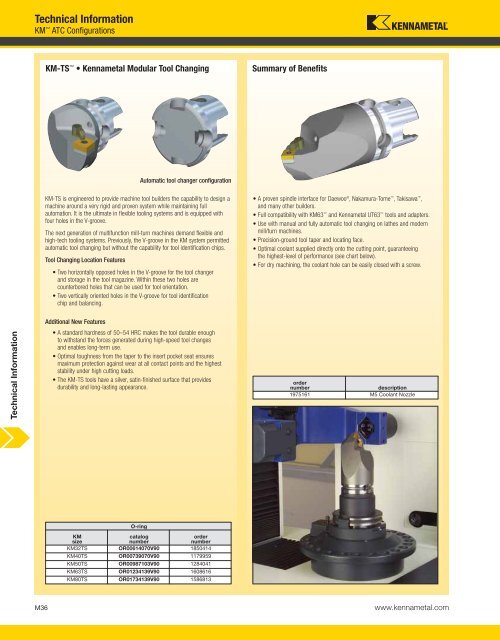

KM-TS • Kennametal Modular Tool Changing<br />

Automatic tool changer configuration<br />

KM-TS is engineered to provide machine tool builders the capability to design a<br />

machine around a very rigid and proven system while maintaining full<br />

automation. It is the ultimate in flexible tooling systems and is equipped with<br />

four holes in the V-groove.<br />

The next generation of multifunction mill-turn machines demand flexible and<br />

high-tech tooling systems. Previously, the V-groove in the KM system permitted<br />

automatic tool changing but without the capability for tool identification chips.<br />

Tool Changing Location Features<br />

• Two horizontally opposed holes in the V-groove for the tool changer<br />

and storage in the tool magazine. Within these two holes are<br />

counterbored holes that can be used for tool orientation.<br />

• Two vertically oriented holes in the V-groove for tool identification<br />

chip and balancing.<br />

Additional New Features<br />

• A standard hardness of 50–54 HRC makes the tool durable enough<br />

to withstand the forces generated during high-speed tool changes<br />

and enables long-term use.<br />

• Optimal toughness from the taper to the insert pocket seat ensures<br />

maximum protection against wear at all contact points and the highest<br />

stability under high cutting loads.<br />

• The KM-TS tools have a silver, satin-finished surface that provides<br />

durability and long-lasting appearance.<br />

O-ring<br />

KM<br />

size<br />

catalog<br />

number<br />

order<br />

number<br />

KM32TS OR00614070V90 1850414<br />

KM40TS OR00739070V90 1179959<br />

KM50TS OR00987103V90 1284041<br />

KM63TS OR01234139V90 1608616<br />

KM80TS OR01734139V90 1586813<br />

Summary of Benefits<br />

• A proven spindle interface for Daewoo ® , Nakamura-Tome , Takisawa ,<br />

and many other builders.<br />

• Full compatibility with KM63 and Kennametal UT63 tools and adapters.<br />

• Use with manual and fully automatic tool changing on lathes and modern<br />

mill/turn machines.<br />

• Precision-ground tool taper and locating face.<br />

• Optimal coolant supplied directly onto the cutting point, guaranteeing<br />

the highest-level of performance (see chart below).<br />

• For dry machining, the coolant hole can be easily closed with a screw.<br />

order<br />

number description<br />

1975161 M5 Coolant Nozzle<br />

M36 www.kennametal.com