You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

KM Manual Clamping Unit • Disassembly Procedures (continued)<br />

6. Clean locking balls, torque screw, lockrod, and bump-off pin of all<br />

grease and inspect for wear, burrs, or obvious damage. If rebuilding the<br />

unit with a repair parts package, we recommend using all new components<br />

contained in the kit. If you are not using the repair package, but are retiming<br />

or adjusting the unit, inspect the external threads on the torque screw and<br />

lockrod, the locking ball contact surfaces on the lockrod, and the mating<br />

surfaces between the lockrod and bump-off pin. Discard any components<br />

of questionable condition and replace with new ones. Note the condition<br />

of the raised taper key on the lockrod as you will need this later.<br />

www.kennametal.com<br />

<strong>Technical</strong> <strong>Information</strong><br />

KM Manual Clamping System<br />

7. Inspect inside the KM taper for damage and/or contamination. Clean the taper<br />

and canister with solvent. Allow the unit to dry before reassembling. Inspect the<br />

torque screw threads in the body for damage.<br />

8. If the unit is equipped for through-coolant capability, you may want to verify<br />

that the coolant passages are clear. Clean if required.<br />

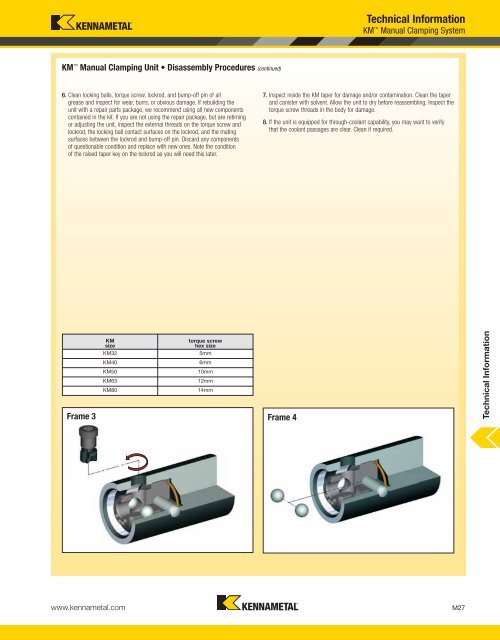

KM<br />

torque screw<br />

size<br />

hex size<br />

KM32 5mm<br />

KM40 6mm<br />

KM50 10mm<br />

<strong>Information</strong><br />

KM63 12mm<br />

KM80 14mm<br />

Frame 3 Frame 4 <strong>Technical</strong><br />

M27