You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

KM Micro /KM Mini Manual Clamping System<br />

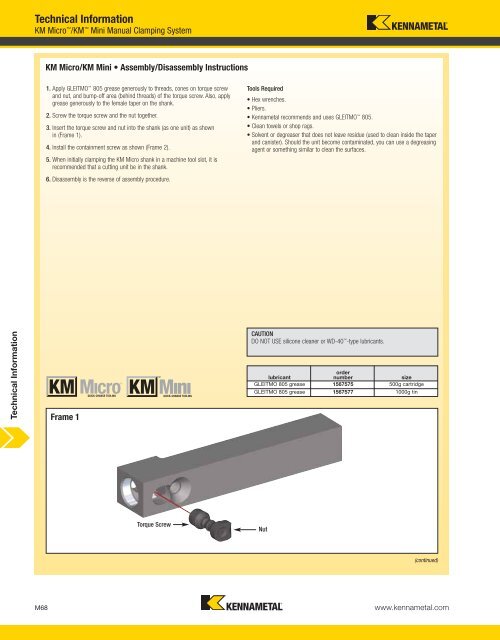

KM Micro/KM Mini • Assembly/Disassembly Instructions<br />

1. Apply GLEITMO 805 grease generously to threads, cones on torque screw<br />

and nut, and bump-off area (behind threads) of the torque screw. Also, apply<br />

grease generously to the female taper on the shank.<br />

2. Screw the torque screw and the nut together.<br />

3. Insert the torque screw and nut into the shank (as one unit) as shown<br />

in (Frame 1).<br />

4. Install the containment screw as shown (Frame 2).<br />

5. When initially clamping the KM Micro shank in a machine tool slot, it is<br />

recommended that a cutting unit be in the shank.<br />

6. Disassembly is the reverse of assembly procedure.<br />

Frame 1<br />

Torque Screw<br />

Tools Required<br />

• Hex wrenches.<br />

• Pliers.<br />

• Kennametal recommends and uses GLEITMO 805.<br />

• Clean towels or shop rags.<br />

• Solvent or degreaser that does not leave residue (used to clean inside the taper<br />

and canister). Should the unit become contaminated, you can use a degreasing<br />

agent or something similar to clean the surfaces.<br />

CAUTION<br />

DO NOT USE silicone cleaner or WD-40 -type lubricants.<br />

order<br />

lubricant<br />

number size<br />

GLEITMO 805 grease 1567575 500g cartridge<br />

GLEITMO 805 grease 1567577 1000g tin<br />

(continued)<br />

M68 www.kennametal.com<br />

Nut