You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

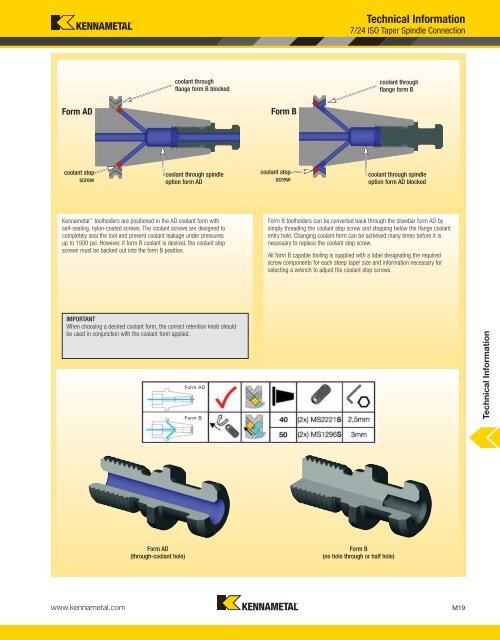

coolant stop<br />

screw<br />

Kennametal toolholders are positioned in the AD coolant form with<br />

self-sealing, nylon-coated screws. The coolant screws are designed to<br />

completely seal the tool and prevent coolant leakage under pressures<br />

up to 1500 psi. However, if form B coolant is desired, the coolant stop<br />

screws must be backed out into the form B position.<br />

www.kennametal.com<br />

coolant through<br />

flange form B blocked<br />

Form AD Form B<br />

coolant through spindle<br />

option form AD<br />

IMPORTANT<br />

When choosing a desired coolant form, the correct retention knob should<br />

be used in conjunction with the coolant form applied.<br />

Form AD<br />

(through-coolant hole)<br />

coolant stop<br />

screw<br />

<strong>Technical</strong> <strong>Information</strong><br />

7/24 ISO Taper Spindle Connection<br />

coolant through<br />

flange form B<br />

coolant through spindle<br />

option form AD blocked<br />

Form B toolholders can be converted back through the drawbar form AD by<br />

simply threading the coolant stop screw and stopping below the flange coolant<br />

entry hole. Changing coolant form can be achieved many times before it is<br />

necessary to replace the coolant stop screw.<br />

All form B capable tooling is supplied with a label designating the required<br />

screw components for each steep taper size and information necessary for<br />

selecting a wrench to adjust the coolant stop screws.<br />

Form B<br />

(no hole through or half hole)<br />

M19<br />

<strong>Technical</strong> <strong>Information</strong>