You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

Balancing<br />

Balancing<br />

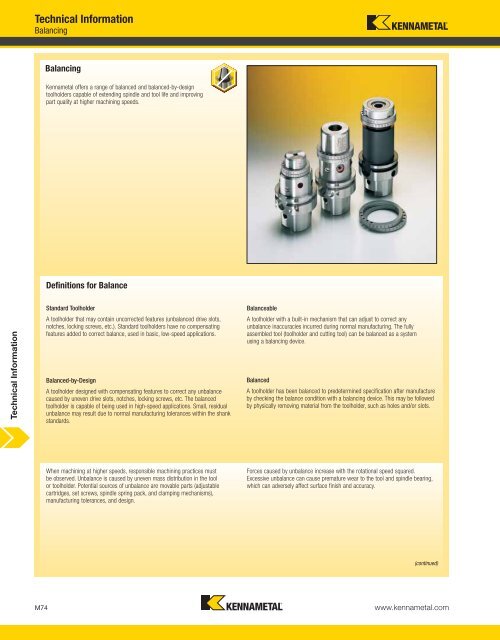

Kennametal offers a range of balanced and balanced-by-design<br />

toolholders capable of extending spindle and tool life and improving<br />

part quality at higher machining speeds.<br />

Definitions for Balance<br />

Standard Toolholder<br />

A toolholder that may contain uncorrected features (unbalanced drive slots,<br />

notches, locking screws, etc.). Standard toolholders have no compensating<br />

features added to correct balance, used in basic, low-speed applications.<br />

Balanced-by-Design<br />

A toolholder designed with compensating features to correct any unbalance<br />

caused by uneven drive slots, notches, locking screws, etc. The balanced<br />

toolholder is capable of being used in high-speed applications. Small, residual<br />

unbalance may result due to normal manufacturing tolerances within the shank<br />

standards.<br />

When machining at higher speeds, responsible machining practices must<br />

be observed. Unbalance is caused by uneven mass distribution in the tool<br />

or toolholder. Potential sources of unbalance are movable parts (adjustable<br />

cartridges, set screws, spindle spring pack, and clamping mechanisms),<br />

manufacturing tolerances, and design.<br />

Balanceable<br />

A toolholder with a built-in mechanism that can adjust to correct any<br />

unbalance inaccuracies incurred during normal manufacturing. The fully<br />

assembled tool (toolholder and cutting tool) can be balanced as a system<br />

using a balancing device.<br />

Balanced<br />

A toolholder has been balanced to predetermined specification after manufacture<br />

by checking the balance condition with a balancing device. This may be followed<br />

by physically removing material from the toolholder, such as holes and/or slots.<br />

Forces caused by unbalance increase with the rotational speed squared.<br />

Excessive unbalance can cause premature wear to the tool and spindle bearing,<br />

which can adversely affect surface finish and accuracy.<br />

(continued)<br />

M74 www.kennametal.com