You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Information</strong><br />

<strong>Technical</strong> <strong>Information</strong><br />

KM Manual Clamping System<br />

KM Manual Clamping Operating Instructions (KM32–KM80)<br />

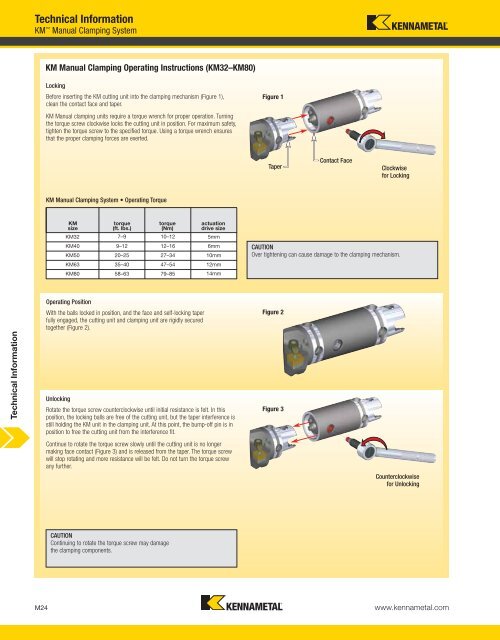

Locking<br />

Before inserting the KM cutting unit into the clamping mechanism (Figure 1),<br />

clean the contact face and taper.<br />

KM Manual clamping units require a torque wrench for proper operation. Turning<br />

the torque screw clockwise locks the cutting unit in position. For maximum safety,<br />

tighten the torque screw to the specified torque. Using a torque wrench ensures<br />

that the proper clamping forces are exerted.<br />

KM Manual Clamping System • Operating Torque<br />

KM<br />

size<br />

torque<br />

(ft. lbs.)<br />

torque<br />

(Nm)<br />

Operating Position<br />

With the balls locked in position, and the face and self-locking taper<br />

fully engaged, the cutting unit and clamping unit are rigidly secured<br />

together (Figure 2).<br />

Unlocking<br />

Rotate the torque screw counterclockwise until initial resistance is felt. In this<br />

position, the locking balls are free of the cutting unit, but the taper interference is<br />

still holding the KM unit in the clamping unit. At this point, the bump-off pin is in<br />

position to free the cutting unit from the interference fit.<br />

Continue to rotate the torque screw slowly until the cutting unit is no longer<br />

making face contact (Figure 3) and is released from the taper. The torque screw<br />

will stop rotating and more resistance will be felt. Do not turn the torque screw<br />

any further.<br />

CAUTION<br />

Continuing to rotate the torque screw may damage<br />

the clamping components.<br />

actuation<br />

drive size<br />

KM32 7–9 10–12 5mm<br />

KM40 9–12 12–16 6mm<br />

KM50 20–25 27–34 10mm<br />

KM63 35–40 47–54 12mm<br />

KM80 58–63 79–85 14mm<br />

Figure 1<br />

Contact Face<br />

Taper Clockwise<br />

for Locking<br />

CAUTION<br />

Over tightening can cause damage to the clamping mechanism.<br />

Figure 2<br />

Figure 3<br />

Counterclockwise<br />

for Unlocking<br />

M24 www.kennametal.com