ECL Comfort 210/310, A275/A375 Installation Guide - Danfoss ...

ECL Comfort 210/310, A275/A375 Installation Guide - Danfoss ...

ECL Comfort 210/310, A275/A375 Installation Guide - Danfoss ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Installation</strong> <strong>Guide</strong> <strong>ECL</strong> <strong>Comfort</strong> <strong>210</strong> / <strong>310</strong>, application <strong>A275</strong> / <strong>A375</strong><br />

The application <strong>A375</strong>.1 is very flexible. These are the basic<br />

principles:<br />

The applications <strong>A375</strong>.1 / <strong>A375</strong>.2 / <strong>A375</strong>.3 can ON / OFF control up<br />

to 8 burner steps.<br />

In application <strong>A375</strong>.1 the first 4 burner steps are controlled by<br />

relays in the <strong>ECL</strong> <strong>310</strong>. The next, max. 4 burner steps, are controlled<br />

by relays in the extension module ECA 32 (placed in the base part<br />

of the <strong>ECL</strong> <strong>310</strong>).<br />

Heating (circuit 1):<br />

Typically, the common boiler temperature is adjusted according to<br />

your requirements. The boiler temperature sensor S3 is the most<br />

important sensor. It must be placed correctly in order to measure<br />

the common boiler temperature. The desired boiler temperature<br />

at S3 is calculated in the <strong>ECL</strong> controller, based on the outdoor<br />

temperature (S1). The lower the outdoor temperature, the higher<br />

the desired boiler temperature. The boiler temperature is also the<br />

flow temperature in the direct connected heating circuit.<br />

By means of a week schedule (up to 3 ‘<strong>Comfort</strong>’ periods / day), the<br />

heating circuit can be in ‘<strong>Comfort</strong>’ or ‘Saving’ mode (two different<br />

temperature values for the desired room temperature). In 'Saving'<br />

mode a 'Total stop' function can be selected in order to switch OFF<br />

the heating.<br />

The first burner step is switched ON when the common boiler<br />

temperature is lower than the desired boiler temperature. The<br />

controller observes the common boiler temperature and switches<br />

ON the next burner step if the common boiler temperature does<br />

not increase satisfactorily. The switching OFF procedure of burner<br />

steps is vice versa. A switching difference determines the ON / OFF<br />

control.<br />

The burners can be controlled in:<br />

• fixed sequence (example: Always 1-2-3-4-5) or<br />

• automatic rotating sequence (example: First period: 1-2-3-4-5,<br />

second period: 2-3-4-5-1, third period: 3-4-5-1-2 and so on)<br />

• semi-automatic rotating sequence (example: First period: 1,<br />

2-3-4-5, second period: 1, 3-4-5-2, third period: 1, 4-5-2-3 and<br />

so on)<br />

Furthermore, the boiler protection function will switch ON the<br />

circulation pump when the boiler temperature gets above a<br />

minimum value. A minimum ON-time can be set for the burner in<br />

order to increase the boiler's efficiency.<br />

The return temperature (S5) to the boiler should not be too<br />

high (condensing boiler) or too low (oil or gas fired boiler). If so,<br />

the desired boiler temperature can be decreased or increased.<br />

Furthermore, the return temperature limitation can be dependent<br />

of the outdoor temperature. Typically, the lower the outdoor<br />

temperature, the higher the accepted return temperature.<br />

If the measured room temperature (S7 or Remote control unit ECA<br />

30) does not equal the desired room temperature, the desired<br />

boiler temperature can be adjusted.<br />

The circulation pump (P1) is ON at heat demand or at frost<br />

protection.<br />

The heating can be switched OFF when the outdoor temperature is<br />

higher than a set value.<br />

The desired common boiler temperature can, via S10, be controlled<br />

by means of an external voltage in the range 0-10 volt.<br />

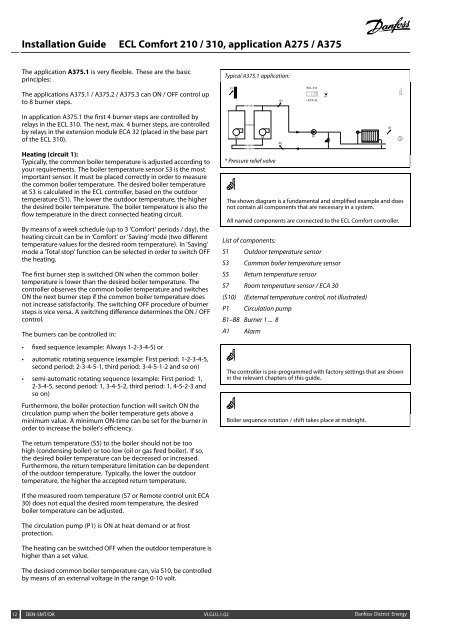

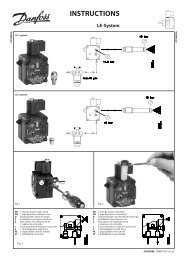

Typical <strong>A375</strong>.1 application:<br />

S1<br />

B1 B8<br />

* Pressure relief valve<br />

S3<br />

S5<br />

<strong>ECL</strong> <strong>310</strong><br />

+ ECA 32<br />

P1<br />

The shown diagram is a fundamental and simplified example and does<br />

not contain all components that are necessary in a system.<br />

All named components are connected to the <strong>ECL</strong> <strong>Comfort</strong> controller.<br />

List of components:<br />

S1 Outdoor temperature sensor<br />

S3 Common boiler temperature sensor<br />

S5 Return temperature sensor<br />

S7 Room temperature sensor / ECA 30<br />

(S10) (External temperature control, not illustrated)<br />

P1 Circulation pump<br />

B1–B8 Burner 1 ... 8<br />

A1 Alarm<br />

The controller is pre-programmed with factory settings that are shown<br />

in the relevant chapters of this guide.<br />

Boiler sequence rotation / shift takes place at midnight.<br />

12 DEN-SMT/DK VI.GU.L1.02 <strong>Danfoss</strong> District Energy<br />

A1<br />

*<br />

S7<br />

①<br />

<strong>Danfoss</strong><br />

87H2182.10