Boxoffice-April.07.1958

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I<br />

condensers<br />

How to Locate and Correct Trouble in Sound Systems • Part 1<br />

FIVE MOST COMMON TROUBLEMAKERS IN SOUND<br />

DUE TO SIMPLE CAUSES AND EASILY CORRECTED<br />

Preventive Maintenance Is<br />

an Important Factor for Good Results<br />

By<br />

'<br />

WESLEY TROUT<br />

*5<br />

\JvR MAIL<br />

brings requests for<br />

simplified ins:<br />

ructions on servicing<br />

leading makes of<br />

theatre sound systems.<br />

In view of the<br />

fact that many theatres<br />

do not liave regular<br />

sound service, we<br />

present some instructions<br />

on general<br />

Wesley Trout<br />

maintenance which<br />

should prove helpful in better operation<br />

and better quality in sound reproduction,<br />

moreover, it will help you locate components<br />

which may cause trouble.<br />

TECHNICAL TERMS AVOIDED<br />

We have dispensed with too highly technical<br />

terms that might prove more confusing<br />

than helpful. In most any technical<br />

discussion, some technical terms are necessary,<br />

of course.<br />

Let us start off by pointing out that when<br />

sound trouble does develop, some defect in<br />

the circuit, such as a resistor, condenser,<br />

transformer or choke has become defective<br />

and not the entire circuit or components.<br />

Pin your trouble down, if possible, by observation<br />

of various parts. If a short has<br />

developed, smell to see if some component<br />

has burned out. or if there is a short somewhere,<br />

etc. Keep a cool head but work as<br />

swiftly as possible. When checking for<br />

trouble, the use of a multimeter cannot be<br />

beat. !7i most cases. An elaborate array of<br />

electronic equipment is not always necessary<br />

to find and correct trouble in the<br />

sound system. However, when tuning up a<br />

sound system, some special equipment is<br />

necessary.<br />

SHOULD STUDY EQUIPMENT<br />

We do want to emphasize the importance<br />

of making a very careful study of your<br />

complete sound system—a complete understanding<br />

of the function of each unit and<br />

its location. All manufacturers supply some<br />

instructions on operating and maintenance<br />

of their equipment, but seldom is this infonnation<br />

complete enough for good maintenance<br />

of any equipment. One needs to<br />

know the correct voltages necessary at the<br />

tube elements, the values of resistors, condensers,<br />

etc., in order to do a tip-top job<br />

of maintenance. You must have a schematic<br />

of the amplifiers, either from the<br />

manufacturer or draw one, but the latter<br />

is quite a task. Most leading manufacturers Checking some of our inspection sheets,<br />

will furnish schematics free.<br />

over a period of years, we find the second<br />

While there is an almost infinite variety troublemakers on our list are capacitors<br />

of things that can go wrong with electromechanical<br />

equipment as complex as a greater amount of failures than any other<br />

Capacitors account for a<br />

I .<br />

modern theatre sound system, the great component. There are some amplifiers using<br />

plug-in capacitors, but in most cases<br />

majority, we have found from experience,<br />

are troubles due to simple causes, and can they are soldered in. A capacitor can be<br />

be just as simply corrected once located. A checked with an ohmmeter, but one end of<br />

working knowledge of your equipment is a it must be unsoldered. For testing condensers<br />

or resistors in the circuit, there is<br />

"must." Understand the function of each<br />

part: namely, resistors, condensers, chokes available a checker in kit form or factorywired.<br />

R-om radio supply houses they can<br />

and transformers. Check each component<br />

by using your schematic or parts catalog. be purchased from $20 up. However, for<br />

the projection room, usually a<br />

Our many good ohmmeter<br />

will suffice.<br />

years of experience in the field<br />

of servicing have shown that more troubles<br />

involve failures in vacuum tubes than any<br />

of the other components, the exception<br />

OTHER TROUBLE CAUSES<br />

being<br />

condensers. That is the reason tubes The other components that may cause<br />

still remain in the plug-in class for quick trouble are resistors, chokes and transformers.<br />

In order to check a resistor, it<br />

replacement. Good sound reproduction,<br />

sufficient power, depend upon tubes in will be necessary to unfasten one end. Resistors<br />

are very important in securing the<br />

first-class condition, and they should be a<br />

well-known brand for long service. Moreover,<br />

tubes must fit snugly in their sockets plifier, in conjunction with capacitors and<br />

correct voltages and operation of your am-<br />

and the prongs be kept clean for good contact.<br />

elements are absolutely necessary if the<br />

transformers. Correct voltages at the tube<br />

amplifier is to function efficiently. Always<br />

use exact duplicate when replacing resistors<br />

or capacitors.<br />

We can honestly say the above five classifications<br />

include the large percentage of<br />

amplifier components which may cause<br />

trouble, and we have listed them in their<br />

importance. These components are important<br />

in the proper operation of the amplifier<br />

or amplifiers, likewise important in<br />

good quality sound reproduction in any<br />

make or type of sound equipment.<br />

These components are generally rated<br />

far above lin voltage safety) capacity then<br />

absolutely necessary, but this is a safety<br />

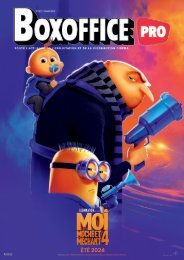

Most 0/ the leading makes of amplHiers have meter precaution. Sometimes a condenser requires<br />

a peak voltage capacity of only 500,<br />

or meters for check'mg tubes and operation of the<br />

push-pull stage. A continuous check on the functioning<br />

of the push-pull output stage is afforded<br />

but generally it is 600-volt i>eak capacity.<br />

by the front panel plate milliameter and associated<br />

ANOTHER SOURCE OF TROUBLE<br />

buttons or suitable switching arrangement as shown<br />

above. This gives the projectionist a good check One frequent source of trouble is electrolytic<br />

capacitors. All manufacturers try to<br />

on the tubes. Simplex equipment has a meter for<br />

checking all the tubes by indicating the condition eliminate any defects in their manufacture,<br />

but occasionally you get one that is<br />

of the tube when the meter pointer is in a certain<br />

"block"—green and red blocks. Instructions are<br />

defective, or will give very short service.<br />

sent on the correct usage of the tube check. Motiogroph,<br />

and some of the other leading equipment Always purchase capacitors, particularly<br />

indicate operation with a milliameter, using buttons<br />

and rotating switch. A meter on amplifiers brand. There are a number of cheap elec-<br />

those in critical circuits, of well-known<br />

gives the projectionist a daily check on his equipment<br />

and its functioning. A check on the output<br />

trolytic capacitors on the market that give<br />

inferior performance and short service, if<br />

stage is very important and most meters will show<br />

they are overloaded. Of course, one should<br />

how nearly "matched" the output tubes are. In<br />

push-pull stages, output tubes should be purchase the correct capacity when making<br />

carefully<br />

matched for maximum performance.— Ampex photo. replacements so that it will not be over<br />

42 The MODERN THEATRE SECTION