Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

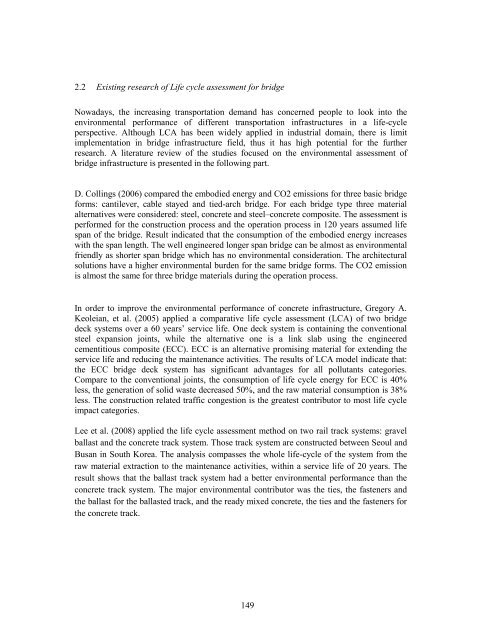

2.2 Exist<strong>in</strong>g research of <strong>Life</strong> cycle assessment for bridge<br />

Nowadays, the <strong>in</strong>creas<strong>in</strong>g transportation demand has concerned people to look <strong>in</strong>to the<br />

environmental performance of different transportation <strong>in</strong>frastructures <strong>in</strong> a life-cycle<br />

perspective. Although LCA has been widely applied <strong>in</strong> <strong>in</strong>dustrial doma<strong>in</strong>, there is limit<br />

implementation <strong>in</strong> bridge <strong>in</strong>frastructure field, thus it has high potential for the further<br />

research. A literature review of the studies focused on the environmental assessment of<br />

bridge <strong>in</strong>frastructure is presented <strong>in</strong> the follow<strong>in</strong>g part.<br />

D. Coll<strong>in</strong>gs (2006) compared the embodied energy and CO2 emissions for three basic bridge<br />

forms: cantilever, cable stayed and tied-arch bridge. For each bridge type three material<br />

alternatives were considered: steel, concrete and steel–concrete composite. The assessment is<br />

performed for the construction process and the operation process <strong>in</strong> 120 years assumed life<br />

span of the bridge. Result <strong>in</strong>dicated that the consumption of the embodied energy <strong>in</strong>creases<br />

with the span length. The well eng<strong>in</strong>eered longer span bridge can be almost as environmental<br />

friendly as shorter span bridge which has no environmental consideration. The architectural<br />

solutions have a higher environmental burden for the same bridge forms. The CO2 emission<br />

is almost the same for three bridge materials dur<strong>in</strong>g the operation process.<br />

In order to improve the environmental performance of concrete <strong>in</strong>frastructure, Gregory A.<br />

Keoleian, et al. (2005) applied a comparative life cycle assessment (LCA) of two bridge<br />

deck systems over a 60 years’ service life. One deck system is conta<strong>in</strong><strong>in</strong>g the conventional<br />

steel expansion jo<strong>in</strong>ts, while the alternative one is a l<strong>in</strong>k slab us<strong>in</strong>g the eng<strong>in</strong>eered<br />

cementitious composite (ECC). ECC is an alternative promis<strong>in</strong>g material for extend<strong>in</strong>g the<br />

service life and reduc<strong>in</strong>g the ma<strong>in</strong>tenance activities. The results of LCA model <strong>in</strong>dicate that:<br />

the ECC bridge deck system has significant advantages for all pollutants categories.<br />

Compare to the conventional jo<strong>in</strong>ts, the consumption of life cycle energy for ECC is 40%<br />

less, the generation of solid waste decreased 50%, and the raw material consumption is 38%<br />

less. The construction related traffic congestion is the greatest contributor to most life cycle<br />

impact categories.<br />

Lee et al. (2008) applied the life cycle assessment method on two rail track systems: gravel<br />

ballast and the concrete track system. Those track system are constructed between Seoul and<br />

Busan <strong>in</strong> South Korea. The analysis compasses the whole life-cycle of the system from the<br />

raw material extraction to the ma<strong>in</strong>tenance activities, with<strong>in</strong> a service life of 20 years. The<br />

result shows that the ballast track system had a better environmental performance than the<br />

concrete track system. The major environmental contributor was the ties, the fasteners and<br />

the ballast for the ballasted track, and the ready mixed concrete, the ties and the fasteners for<br />

the concrete track.<br />

149

![Weibull [Compatibility Mode]](https://img.yumpu.com/48296360/1/190x134/weibull-compatibility-mode.jpg?quality=85)