Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

New composite high performance silicate materials (fibre concrete FC <strong>in</strong> the form of high<br />

performance concrete HPC and ultra high performance concrete UHPC) could be used for construction<br />

of more strong, more durable and at the same time slender structures. The optimized<br />

lightened shape of structural elements demands less material and consequently thus has improved<br />

environmental parameters of the entire structure.<br />

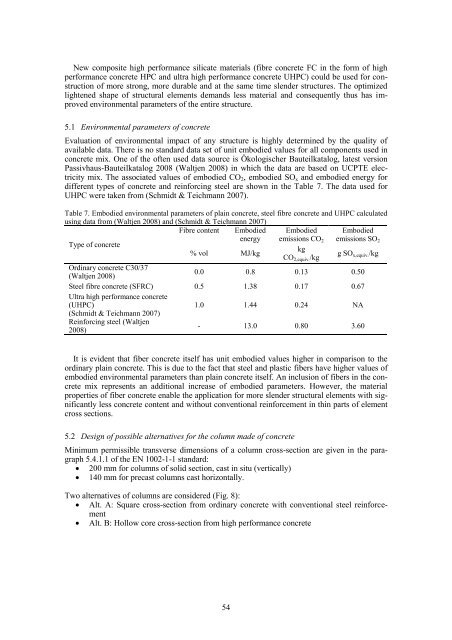

5.1 Environmental parameters of concrete<br />

Evaluation of environmental impact of any structure is highly determ<strong>in</strong>ed by the quality of<br />

available data. There is no standard data set of unit embodied values for all components used <strong>in</strong><br />

concrete mix. One of the often used data source is Ökologischer Bauteilkatalog, latest version<br />

Passivhaus-Bauteilkatalog 2008 (Waltjen 2008) <strong>in</strong> which the data are based on UCPTE electricity<br />

mix. The associated values of embodied CO 2 , embodied SO x and embodied energy for<br />

different types of concrete and re<strong>in</strong>forc<strong>in</strong>g steel are shown <strong>in</strong> the Table 7. The data used for<br />

UHPC were taken from (Schmidt & Teichmann 2007).<br />

Table 7. Embodied environmental parameters of pla<strong>in</strong> concrete, steel fibre concrete and UHPC calculated<br />

us<strong>in</strong>g data from (Waltjen 2008) and (Schmidt & Teichmann 2007)<br />

Fibre content Embodied Embodied Embodied<br />

Type of concrete<br />

energy emissions CO 2 emissions SO 2<br />

% vol MJ/kg<br />

kg<br />

CO 2,equiv. /kg<br />

g SO x,equiv. /kg<br />

Ord<strong>in</strong>ary concrete C30/37<br />

(Waltjen 2008)<br />

0.0 0.8 0.13 0.50<br />

Steel fibre concrete (SFRC) 0.5 1.38 0.17 0.67<br />

Ultra high performance concrete<br />

(UHPC)<br />

1.0 1.44 0.24 NA<br />

(Schmidt & Teichmann 2007)<br />

Re<strong>in</strong>forc<strong>in</strong>g steel (Waltjen<br />

2008)<br />

- 13.0 0.80 3.60<br />

It is evident that fiber concrete itself has unit embodied values higher <strong>in</strong> comparison to the<br />

ord<strong>in</strong>ary pla<strong>in</strong> concrete. This is due to the fact that steel and plastic fibers have higher values of<br />

embodied environmental parameters than pla<strong>in</strong> concrete itself. An <strong>in</strong>clusion of fibers <strong>in</strong> the concrete<br />

mix represents an additional <strong>in</strong>crease of embodied parameters. However, the material<br />

properties of fiber concrete enable the application for more slender structural elements with significantly<br />

less concrete content and without conventional re<strong>in</strong>forcement <strong>in</strong> th<strong>in</strong> parts of element<br />

cross sections.<br />

5.2 Design of possible alternatives for the column made of concrete<br />

M<strong>in</strong>imum permissible transverse dimensions of a column cross-section are given <strong>in</strong> the paragraph<br />

5.4.1.1 of the EN 1002-1-1 standard:<br />

200 mm for columns of solid section, cast <strong>in</strong> situ (vertically)<br />

140 mm for precast columns cast horizontally.<br />

Two alternatives of columns are considered (Fig. 8):<br />

Alt. A: Square cross-section from ord<strong>in</strong>ary concrete with conventional steel re<strong>in</strong>forcement<br />

Alt. B: Hollow core cross-section from high performance concrete<br />

54

![Weibull [Compatibility Mode]](https://img.yumpu.com/48296360/1/190x134/weibull-compatibility-mode.jpg?quality=85)