Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

nario. That means, flows of the recycled material will be taken as <strong>in</strong>put <strong>in</strong> the production<br />

process of the next product.<br />

2. The follow<strong>in</strong>g transport distances are <strong>in</strong>cluded:<br />

- Transport of raw materials from extraction/supplier to manufacturer.<br />

- Transport of steel products from steel mill to wholesaler (average distance estimated<br />

to 900 km)<br />

- Transport of steel products from wholesaler to manufacturer of steel frames (average<br />

distance estimated to 100 km)<br />

- Transport of build<strong>in</strong>g products from manufacturer to build<strong>in</strong>g site (average distance<br />

estimated to 400 km)<br />

- Transport from build<strong>in</strong>g site to recycl<strong>in</strong>g/<strong>in</strong>c<strong>in</strong>eration and land fill (average distance<br />

estimated to 50 km)<br />

Transport data is based on The Norwegian Emission Inventory (SFT - Norwegian<br />

Pollution Control Authority, February 2000).<br />

3. Data on energy consumption on the build<strong>in</strong>g site is based on <strong>in</strong>formation given by<br />

Contiga AS.<br />

4. The column does not need any mechanical ma<strong>in</strong>tenance dur<strong>in</strong>g the use phase. Average<br />

service life of the pa<strong>in</strong>t is expected to be 60 years. This is based on that the loss<br />

of pa<strong>in</strong>t will be 1,3 μm a year (Corrosion category C1 2 ) and that the m<strong>in</strong>imum thickness<br />

of the pa<strong>in</strong>t will be between 80 and 120 μm. The build<strong>in</strong>g frame structure will<br />

not be pa<strong>in</strong>ted dur<strong>in</strong>g the service life of the build<strong>in</strong>g (60 years). The steel products<br />

will have no impact on the <strong>in</strong>door environment.<br />

5. Energy consumption on demolition is assumed to be the same as for the build<strong>in</strong>g site.<br />

6. The use/ma<strong>in</strong>tenance phase and the demolition phase are based on a typical scenario<br />

for the product. End of life scenario is <strong>in</strong>cluded <strong>in</strong> LCI data for the steel products and<br />

is based on a recovery rate (RR) of 96 %. Recovery rate is the fraction of steel recovered<br />

as scrap dur<strong>in</strong>g one life cycle of a steel product. The flows of the recycled material<br />

will then become <strong>in</strong>puts <strong>in</strong>to the production of the next product.<br />

Accord<strong>in</strong>g to TIBNOR AB (TIBNOR 2009), a Swedish company which sells steel long products,<br />

the column costs 16.65 SEK/kg which is approximately 49 Euro for the complete column.<br />

Costs after the factory gate are the build<strong>in</strong>g site specific.<br />

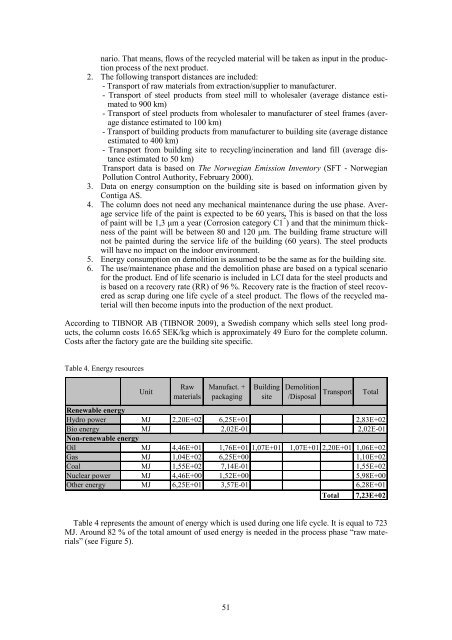

Table 4. Energy resources<br />

Unit<br />

Raw<br />

materials<br />

Manufact. +<br />

packag<strong>in</strong>g<br />

Build<strong>in</strong>g<br />

site<br />

Demolition<br />

/Disposal<br />

Transport<br />

Renewable energy<br />

Hydro power MJ 2,20E+02 6,25E+01 2,83E+02<br />

Bio energy MJ 2,02E-01 2,02E-01<br />

Non-renewable energy<br />

Oil MJ 4,46E+01 1,76E+01 1,07E+01 1,07E+01 2,20E+01 1,06E+02<br />

Gas MJ 1,04E+02 6,25E+00 1,10E+02<br />

Coal MJ 1,55E+02 7,14E-01 1,55E+02<br />

Nuclear power MJ 4,46E+00 1,52E+00 5,98E+00<br />

Other energy MJ 6,25E+01 3,57E-01 6,28E+01<br />

Total 7,23E+02<br />

Total<br />

Table 4 represents the amount of energy which is used dur<strong>in</strong>g one life cycle. It is equal to 723<br />

MJ. Around 82 % of the total amount of used energy is needed <strong>in</strong> the process phase “raw materials”<br />

(see Figure 5).<br />

51

![Weibull [Compatibility Mode]](https://img.yumpu.com/48296360/1/190x134/weibull-compatibility-mode.jpg?quality=85)