Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6. FUTURE TECHNICAL DEVELOPMENTS<br />

Now that the „FlexiArch‟ system has been found to perform exceptionally well for spans<br />

rang<strong>in</strong>g from 4m to 15m with different span/rise ratios the follow<strong>in</strong>g, which could widen its<br />

potential market, are be<strong>in</strong>g considered:<br />

a) Increas<strong>in</strong>g the maximum span to 20m (or possible higher).<br />

b) Adapt<strong>in</strong>g the „FlexiArch‟ system for skew arch bridges with angles of skew up to 30 o .<br />

Standard voussoirs can be utilised and a 5m span x 2m rise x 3m wide system will be<br />

tested shortly.<br />

c) Alter<strong>in</strong>g the geometry of the arch from a segment of a circle, which has been utilised to<br />

date, to <strong>in</strong>clude pseudo elliptical, made up of a comb<strong>in</strong>ation of circular profiles.<br />

Develop method statements for the use of „FlexiArch‟ units for:<br />

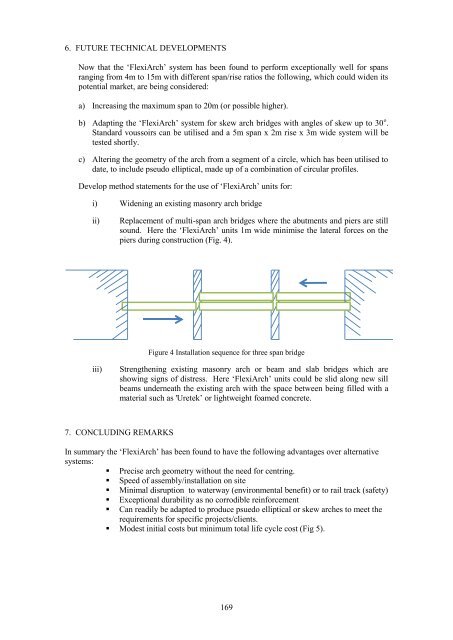

i) Widen<strong>in</strong>g an exist<strong>in</strong>g masonry arch bridge<br />

ii)<br />

Replacement of multi-span arch bridges where the abutments and piers are still<br />

sound. Here the „FlexiArch‟ units 1m wide m<strong>in</strong>imise the lateral forces on the<br />

piers dur<strong>in</strong>g construction (Fig. 4).<br />

Figure 4 Installation sequence for three span bridge<br />

iii)<br />

Strengthen<strong>in</strong>g exist<strong>in</strong>g masonry arch or beam and slab bridges which are<br />

show<strong>in</strong>g signs of distress. Here „FlexiArch‟ units could be slid along new sill<br />

beams underneath the exist<strong>in</strong>g arch with the space between be<strong>in</strong>g filled with a<br />

material such as 'Uretek‟ or lightweight foamed concrete.<br />

7. CONCLUDING REMARKS<br />

In summary the „FlexiArch‟ has been found to have the follow<strong>in</strong>g advantages over alternative<br />

systems:<br />

• Precise arch geometry without the need for centr<strong>in</strong>g.<br />

• Speed of assembly/<strong>in</strong>stallation on site<br />

• M<strong>in</strong>imal disruption to waterway (environmental benefit) or to rail track (safety)<br />

• Exceptional durability as no corrodible re<strong>in</strong>forcement<br />

• Can readily be adapted to produce psuedo elliptical or skew arches to meet the<br />

requirements for specific projects/clients.<br />

• Modest <strong>in</strong>itial costs but m<strong>in</strong>imum total life cycle cost (Fig 5).<br />

169

![Weibull [Compatibility Mode]](https://img.yumpu.com/48296360/1/190x134/weibull-compatibility-mode.jpg?quality=85)