Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4 LIFE CYCLE INVENTORY<br />

4.1 Methodology<br />

LCA methodologies are described <strong>in</strong> a series of <strong>in</strong>ternational standards (ISO 14040, ISO 14041<br />

to ISO 14044) sett<strong>in</strong>g the rules for conduct<strong>in</strong>g LCA. The International Iron and steel <strong>in</strong>stitute<br />

has been provid<strong>in</strong>g <strong>in</strong>ventory for steel products, from cradle to gate of factory s<strong>in</strong>ce 1995 (see<br />

worldsteel.org, Curran et al. 2006). But at that time, scrap was considered as a raw material with<br />

neither burden, nor credit though us<strong>in</strong>g secondary raw materials saves energy and reduces the<br />

environmental impacts. Nowadays, <strong>in</strong>dustries have worked aggressively to <strong>in</strong>fluence the methodology<br />

and <strong>in</strong>clude the end-of-life (EOL) treatment and recycl<strong>in</strong>g of steel (Amato et al. 1996,<br />

IISI 2005 and 2008, Hiroyuki & Toshiyuki 2005, Birat et al. 2005, Eurofer 2007, Johnson et al.<br />

2008). The pr<strong>in</strong>ciples are (1) steel is considered as a closed-loop material and the ma<strong>in</strong> steps of<br />

its LCA are the manufacture, the use phase and the EOL treatment, (2) LCI data <strong>in</strong>clude the<br />

manufacture and EOL steps, practitioners will have to add the use phase. The important parameters<br />

of the study are (1) the recovery rate RR, the fraction of material that is recaptured after one<br />

life cycle, it <strong>in</strong>cludes the pre-consumer scrap generated dur<strong>in</strong>g the manufactur<strong>in</strong>g process and<br />

the EOL scrap (post-consumer scrap) and (2) the yield Y represent<strong>in</strong>g the ability of the secondary<br />

process to convert scrap <strong>in</strong>to steel. And thus, if X represents the LCI <strong>in</strong>dicator,<br />

X X prim<br />

RR Y (X prim<br />

X rec<br />

) (1)<br />

where X prim = LCI <strong>in</strong>dicator for primary manufacture; X rec = LCI <strong>in</strong>dicator for recycl<strong>in</strong>g<br />

process. It is also demonstrated that equ. (1) is still applicable if recycl<strong>in</strong>g is considered an <strong>in</strong>def<strong>in</strong>ite<br />

number of times.<br />

It was already <strong>in</strong>dicated that sta<strong>in</strong>less steel is recovered to more than 90% (see Table 1). It<br />

should be noted that austenitics are separated from other families thanks to their non-magnetic<br />

property, they are recycled as austenitics whereas ferritics can be recycled as sta<strong>in</strong>less or carbon<br />

steel.<br />

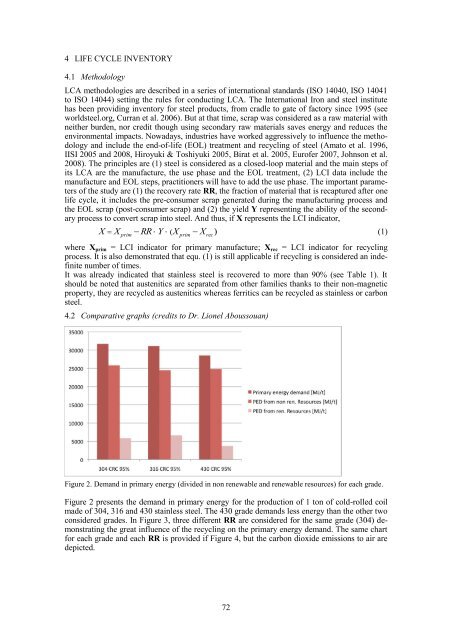

4.2 Comparative graphs (credits to Dr. Lionel Aboussouan)<br />

Figure 2. Demand <strong>in</strong> primary energy (divided <strong>in</strong> non renewable and renewable resources) for each grade.<br />

Figure 2 presents the demand <strong>in</strong> primary energy for the production of 1 ton of cold-rolled coil<br />

made of 304, 316 and 430 sta<strong>in</strong>less steel. The 430 grade demands less energy than the other two<br />

considered grades. In Figure 3, three different RR are considered for the same grade (304) demonstrat<strong>in</strong>g<br />

the great <strong>in</strong>fluence of the recycl<strong>in</strong>g on the primary energy demand. The same chart<br />

for each grade and each RR is provided if Figure 4, but the carbon dioxide emissions to air are<br />

depicted.<br />

72

![Weibull [Compatibility Mode]](https://img.yumpu.com/48296360/1/190x134/weibull-compatibility-mode.jpg?quality=85)