Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Sustainable Construction A Life Cycle Approach in Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The construction of the bridge was performed <strong>in</strong> the follow<strong>in</strong>g sequence:<br />

1. Excavation of the soil down to a level of 2 meters below the end screens.<br />

2. Driv<strong>in</strong>g of 6 tube-shaped steel piles (RR 170x10 mm) per support. The top of each pile<br />

is protected by a 2 meter long pipe shaped pile (RR 600x1.6mm).<br />

3. Cast<strong>in</strong>g of the w<strong>in</strong>g walls and pile cap.<br />

4. Launch<strong>in</strong>g of Steel girders.<br />

5. Cast<strong>in</strong>g of bridge deck and end screens<br />

6. Cast<strong>in</strong>g of the pavement.<br />

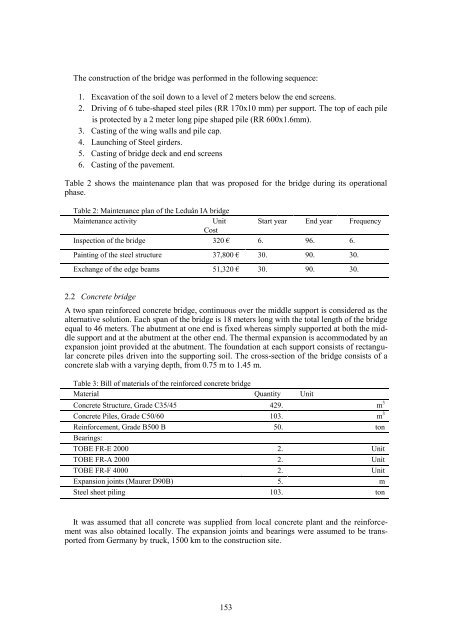

Table 2 shows the ma<strong>in</strong>tenance plan that was proposed for the bridge dur<strong>in</strong>g its operational<br />

phase.<br />

Table 2: Ma<strong>in</strong>tenance plan of the Leduån IA bridge<br />

Ma<strong>in</strong>tenance activity<br />

Unit Start year End year Frequency<br />

Cost<br />

Inspection of the bridge 320 € 6. 96. 6.<br />

Pa<strong>in</strong>t<strong>in</strong>g of the steel structure 37,800 € 30. 90. 30.<br />

Exchange of the edge beams 51,320 € 30. 90. 30.<br />

2.2 Concrete bridge<br />

A two span re<strong>in</strong>forced concrete bridge, cont<strong>in</strong>uous over the middle support is considered as the<br />

alternative solution. Each span of the bridge is 18 meters long with the total length of the bridge<br />

equal to 46 meters. The abutment at one end is fixed whereas simply supported at both the middle<br />

support and at the abutment at the other end. The thermal expansion is accommodated by an<br />

expansion jo<strong>in</strong>t provided at the abutment. The foundation at each support consists of rectangular<br />

concrete piles driven <strong>in</strong>to the support<strong>in</strong>g soil. The cross-section of the bridge consists of a<br />

concrete slab with a vary<strong>in</strong>g depth, from 0.75 m to 1.45 m.<br />

Table 3: Bill of materials of the re<strong>in</strong>forced concrete bridge<br />

Material Quantity Unit<br />

Concrete Structure, Grade C35/45 429. m 3<br />

Concrete Piles, Grade C50/60 103. m 3<br />

Re<strong>in</strong>forcement, Grade B500 B 50. ton<br />

Bear<strong>in</strong>gs:<br />

TOBE FR-E 2000 2. Unit<br />

TOBE FR-A 2000 2. Unit<br />

TOBE FR-F 4000 2. Unit<br />

Expansion jo<strong>in</strong>ts (Maurer D90B) 5. m<br />

Steel sheet pil<strong>in</strong>g 103. ton<br />

It was assumed that all concrete was supplied from local concrete plant and the re<strong>in</strong>forcement<br />

was also obta<strong>in</strong>ed locally. The expansion jo<strong>in</strong>ts and bear<strong>in</strong>gs were assumed to be transported<br />

from Germany by truck, 1500 km to the construction site.<br />

153

![Weibull [Compatibility Mode]](https://img.yumpu.com/48296360/1/190x134/weibull-compatibility-mode.jpg?quality=85)