Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

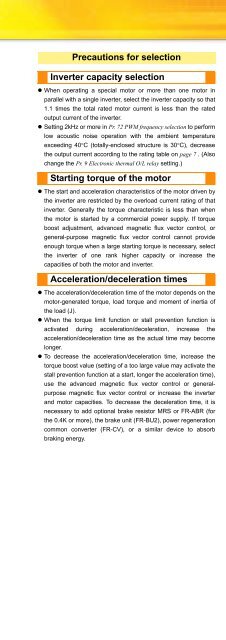

Precautions for selectionInverter capacity selection• When operating a special motor or more than one motor inparallel with a single inverter, select the inverter capacity so that1.1 times the total rated motor current is less than the ratedoutput current of the inverter.• Setting 2kHz or more in Pr. 72 PWM frequency selection to performlow acoustic noise operation with the ambient temperatureexceeding 40°C (totally-enclosed structure is 30°C), decreasethe output current according to the rating table on page 7 . (Alsochange the Pr. 9 Electronic thermal O/L relay setting.)Starting torque of the motor• The start and acceleration characteristics of the motor driven bythe inverter are restricted by the overload current rating of thatinverter. Generally the torque characteristic is less than whenthe motor is started by a commercial power supply. If torqueboost adjustment, advanced magnetic flux vector control, orgeneral-purpose magnetic flux vector control cannot provideenough torque when a large starting torque is necessary, selectthe inverter of one rank higher capacity or increase thecapacities of both the motor and inverter.Acceleration/deceleration times• The acceleration/deceleration time of the motor depends on themotor-generated torque, load torque and moment of inertia ofthe load (J).• When the torque limit function or stall prevention function isactivated during acceleration/deceleration, increase theacceleration/deceleration time as the actual time may becomelonger.• To decrease the acceleration/deceleration time, increase thetorque boost value (setting of a too large value may activate thestall prevention function at a start, longer the acceleration time),use the advanced magnetic flux vector control or generalpurposemagnetic flux vector control or increase the inverterand motor capacities. To decrease the deceleration time, it isnecessary to add optional brake resistor MRS or FR-ABR (forthe 0.4K or more), the brake unit (FR-BU2), power regenerationcommon converter (FR-CV), or a similar device to absorbbraking energy.Power transfer mechanism (reductiongear, belt, chain, etc.)• When an oil-lubricated gear box, speed change/reduction gearor similar device is used in the power transfer system, note thatcontinuous operation at low speed only may deteriorate oillubrication, causing seizure. When performing fast operation athigher than 60Hz, fully note that such operation will causestrength shortage due to the noise, life or centrifugal force of thepower transfer mechanism.Instructions for overload operation• When performing operation of frequent start/stop of the inverter,rise/fall in the temperature of the transistor element of theinverter will repeat due to a repeated flow of large current,shortening the life from thermal fatigue. Since thermal fatigue isrelated to the amount of current, the life can be increased byreducing current at locked condition, starting current, etc.Decreasing current may increase the life. However, decreasingcurrent will result in insufficient torque and the inverter may notstart. Therefore, choose the inverter which has enoughallowance for current.FeaturesOptionsInstructionsInquiryWarrantyCompatibilityMotorPeripheralDevicesStandardSpecificationsOutlineDimensionDrawingsTerminal ConnectionDiagramTerminal SpecificationExplanationOperation panelParameter unitFR ConfiguratorParameterListExplanationsofParametersProtectiveFunctions60