Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

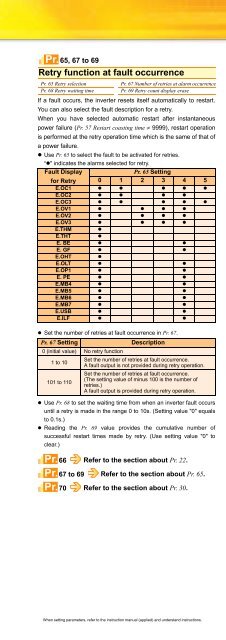

Pr. 65, 67 to 69Retry function at fault occurrencePr. 65 Retry selectionPr. 67 Number of retries at alarm occurrencePr. 68 Retry waiting timePr. 69 Retry count display eraseIf a fault occurs, the inverter resets itself automatically to restart.You can also select the fault description for a retry.When you have selected automatic restart after instantaneouspower failure (Pr. 57 Restart coasting time ≠ 9999), restart operationis performed at the retry operation time which is the same of that ofa power failure.• Use Pr. 65 to select the fault to be activated for retries."•" indicates the alarms selected for retry.Fault DisplayPr. 65 Settingfor Retry 0 1 2 3 4 5E.OC1 • • • • •E.OC2 • • • •E.OC3 • • • • •E.OV1 • • • •E.OV2 • • • •E.OV3 • • • •E.THM •E.THT•E. BE • •E. GF • •E.OHT •E.OLT • •E.OP1 • •E. PE • •E.MB4 • •E.MB5 • •E.MB6 • •E.MB7 • •E.USB • •E.ILF • •• Set the number of retries at fault occurrence in Pr. 67.Pr. 67 Setting0 (initial value) No retry function1 to 10101 to 110DescriptionSet the number of retries at fault occurrence.A fault output is not provided during retry operation.Set the number of retries at fault occurrence.(The setting value of minus 100 is the number ofretries.)A fault output is provided during retry operation.• Use Pr. 68 to set the waiting time from when an inverter fault occursuntil a retry is made in the range 0 to 10s. (Setting value "0" equalsto 0.1s.)• Reading the Pr. 69 value provides the cumulative number ofsuccessful restart times made by retry. (Use setting value "0" toclear.)Pr.Pr.Pr.66 Refer to the section about Pr. 22.67 to 69 Refer to the section about Pr. 65.70 Refer to the section about Pr. 30.Pr. 71, 450Motor selection (applied motor)Pr. 71 Applied motorPr. 450 Second applied motorSetting of the used motor selects the thermal characteristicappropriate for the motor.Setting is required to use a constant-torque motor. Thermalcharacteristic of the electronic thermal relay function suitable forthe motor is set.Pr. 71,Pr. 450SettingThermal Characteristic of theElectronic Thermal RelayFunction54Mitsubishi constanttorqueSF-HRCA◦ ∗25 Standard∗3◦15 Constant-torque ∗3 Direct input of◦motor constants is6 Standard ∗4 enabled ◦16 Constant-torque ∗4 ◦9999 Function invalid (only Pr. 450 can be set, initial value)∗1 Motor constants of Mitsubishi high efficiency motor SF-HR∗2 Motor constants of Mitsubishi constant-torque motor SF-HRCA.∗3 Star connection∗4 Delta connection• For the 5.5K and 7.5K, the Pr. 0 Torque boost and Pr. 12 DC injectionbrake operation voltage settings are automatically changed accordingto the Pr. 71 and Pr. 450 settings as follows.∗1 Pr. 71, Pr. 450 setting: 0, 3 to 6, 23, 24, 40, 43, 44∗2 Pr. 71, Pr. 450 setting: 1, 13 to 16, 50, 53, 54Motor (◦: Motor used)Standard Constant-torque(SF-JR, etc.) (SF-JRCA, etc.)Thermal characteristics of a standard0◦motor (Pr. 71 initial value)Thermal characteristics of the Mitsubishi1◦constant-torque motorThermal characteristic of Mitsubishi high40◦ ∗1efficiency motor SF-HRThermal characteristic of Mitsubishi50◦ ∗2constant torque motor SF-HRCA3 Standard◦13 Constant-torque ◦Mitsubishi standard23 motor SF-JR4P(1.5kW or less)Mitsubishi high43efficiency SF-HRMitsubishi constanttorqueSF-HRCA534 StandardSelect "Offline autotuning setting"Auto tuning datacan be read,changed, and set.◦◦ ∗1◦ ∗2◦14 Constant-torque ◦2444Mitsubishi standardmotor SF-JR4P(1.5kW or less)Mitsubishi highefficiency SF-HRAutomatic ChangeParameterStandard MotorSetting ∗1◦◦ ∗1Constant-torqueMotor Setting ∗2Pr. 0 3% 2%Pr. 12 4% 2%Pr. 72, 240Carrier frequency and Soft-PWMselectionPr. 72 PWM frequency selectionPr. 240 Soft-PWM operation selectionYou can change the motor sound.Pr. SettingDescriptionNumber RangePWM carrier frequency can be changed. Thesetting is in [kHz].72 0 to 15Note that 0 indicates 0.7kHz and 15 indicates14.5kHz.0 Soft-PWM is invalid2401 When Pr. 72 = "0 to 5", Soft-PWM is valid.FeaturesPeripheralDevicesStandardSpecificationsOutlineDimensionDrawingsTerminal ConnectionDiagramTerminal SpecificationExplanationOperation panelParameter unitFR ConfiguratorParameterListExplanationsofParametersProtectiveFunctionsOptionsInstructionsMotorCompatibilityWarrantyInquiryWhen setting parameters, refer to the instruction manual (applied) and understand instructions.34