- Page 4 and 5:

MACHINE NUMBERSThe manufacturing No

- Page 6 and 7:

MACHINE NUMBERSTRANSMISSIONTYPE:MFG

- Page 8 and 9:

CONTENTSMACHINE NUMBERSSAFETYRecogn

- Page 10 and 11:

CONTENTSPeriodic Replacement of Par

- Page 12 and 13:

SAFETYRECOGNIZE SAFETY INFORMATION!

- Page 14 and 15:

SAFETYWEAR PROTECTIVE CLOTHING!" We

- Page 16 and 17:

SAFETYUSE HANDHOLDS AND STEPS!" Fal

- Page 18 and 19:

OPERATE ONLY FROM OPERATOR’S SEAT

- Page 20 and 21:

PROVIDE SIGNALS FOR JOBS INVOLVINGM

- Page 22 and 23:

SAFETYAVOID INJURY FROM ROLLAWAYACC

- Page 24 and 25:

SAFETYKEEP PERSONNEL CLEAR FROM WOR

- Page 26 and 27:

SAFETYDIG WITH CAUTION!" Accidental

- Page 28 and 29:

SAFETYPARK MACHINE SAFELYTo avoid a

- Page 30 and 31:

SAFETYPRACTICE SAFE MAINTENANCETo a

- Page 32 and 33:

SAFETYPREVENT PARTS FROM FLYING!" T

- Page 34 and 35:

SAFETYAVOID HIGH-PRESSURE FLUIDS!"

- Page 36 and 37:

SAFETYCheck Heat Shields:!" Damaged

- Page 38 and 39:

SAFETYAVOID HEATING NEAR PRESSURIZE

- Page 40 and 41:

HANDLE CHEMICAL PRODUCTS SAFELYSAFE

- Page 42 and 43:

SAFETY SIGNS/Europe/Asia/Middle and

- Page 44 and 45:

SAFETY SIGNS/Europe/Asia/Middle and

- Page 46 and 47:

SAFETY SIGNS/Europe/Asia/Middle and

- Page 48 and 49:

COMPONENTS NAMECOMPONENTS NAME1- Bu

- Page 50 and 51:

OPERATOR'S STATIONSTEERING COLUMN C

- Page 52 and 53:

OPERATOR'S STATIONBRAKE PEDAL12CAUT

- Page 54 and 55:

OPERATOR'S STATIONSHIFT LEVER1Trave

- Page 56 and 57:

OPERATOR'S STATIONBRAKE SWITCHBrake

- Page 58 and 59:

OPERATOR'S STATIONWIPER SWITCHTurn

- Page 60 and 61:

COOLANT TEMPERATURE GAUGEEngine coo

- Page 62 and 63:

OPERATOR'S STATIONALTERNATOR INDICA

- Page 64 and 65:

TRIP METER(TRIP METER 1 AND TRIP ME

- Page 66 and 67:

OPERATOR'S STATIONResetting Set-Hou

- Page 68 and 69:

OPERATOR'S STATIONSWITCH PANEL1- En

- Page 70 and 71:

OPERATOR'S STATIONWORK LIGHT SWITCH

- Page 72 and 73:

OPERATOR'S STATIONSWITCH PANEL (Opt

- Page 74 and 75:

OPERATOR'S STATIONHORN SWITCHHorn s

- Page 76 and 77:

OPERATOR'S STATIONCAB LIGHTTurn the

- Page 78 and 79:

OPERATOR'S STATIONSWING LOCK LEVERT

- Page 80 and 81:

OPERATOR'S STATIONAUTO AIR CONDITIO

- Page 82 and 83:

OPERATOR'S STATION!" Temperature Co

- Page 84 and 85:

OPERATOR'S STATIONCOOLING OPERATION

- Page 86 and 87:

OPERATOR'S STATIONAUTO AIR CONDITIO

- Page 88 and 89:

OPERATOR'S STATIONControl Panel Des

- Page 90 and 91:

OPERATOR'S STATION!" Circulation Mo

- Page 92 and 93:

OPERATOR'S STATIONDEFROSTER OPERATI

- Page 94 and 95:

OPERATOR'S STATIONCAB HEATER (Optio

- Page 96 and 97:

OPERATOR'S STATIONDEFROSTER OPERATI

- Page 98 and 99:

OPERATOR'S STATIONStation Presettin

- Page 100 and 101:

OPERATOR'S STATIONStation Presettin

- Page 102 and 103:

CLOSING UPPER FRONT WINDOWOPERATOR'

- Page 104 and 105:

OPERATOR'S STATIONOPENING/CLOSING O

- Page 106 and 107:

OPERATOR'S STATIONADJUSTING THE SEA

- Page 108 and 109:

ADJUSTING THE AIR-SUSPENSION SEAT(O

- Page 110 and 111:

OPERATOR'S STATIONSEAT BELT1 2CAUTI

- Page 112 and 113:

OBSERVE ENGINE OPERATION CLOSELYBRE

- Page 114 and 115:

INSPECT MACHINE DAILY BEFORE START-

- Page 116 and 117:

STARTING THE ENGINE IN ORDINARY TEM

- Page 118 and 119:

CHECK INSTRUMENTS AFTER STARTINGOPE

- Page 120 and 121:

OPERATING THE ENGINEDisconnecting t

- Page 122 and 123:

TRAVELINGCorrect machine operation

- Page 124 and 125:

PrecautionsDRIVING THE MACHINE1. Ch

- Page 126 and 127:

DRIVING THE MACHINE1. Even after th

- Page 128 and 129:

TRAVELING IN WATER OR ON SOFTTERRAI

- Page 130 and 131:

DRIVING THE MACHINEEMERGENCY PARKIN

- Page 132 and 133:

CONTROL LEVER (ISO PATTERN)OPERATIN

- Page 134 and 135:

OPERATING THE MACHINESTEERING WHEEL

- Page 136 and 137:

OPERATING THE MACHINEWarming-up the

- Page 138 and 139:

OPERATING THE MACHINEAUTO-IDLEWith

- Page 140 and 141:

OPERATING THE MACHINEChanging Auto-

- Page 142 and 143:

OPERATING THE MACHINEPOWER MODEOne

- Page 144 and 145:

PRECAUTIONS FOR OPERATIONSOPERATING

- Page 146 and 147:

TRAVELING/OPERATING THE MACHINE ONA

- Page 148 and 149:

OPERATING THE MACHINEEXCAVATION•

- Page 150 and 151:

OPERATING THE MACHINEGRADINGWhile o

- Page 152 and 153:

OPERATING THE MACHINEEMERGENCY BOOM

- Page 154 and 155:

OVERNIGHT STORAGE INSTRUCTIONSOPERA

- Page 156 and 157:

GENERAL TRANSPORTATION HINTSTRANSPO

- Page 158 and 159:

TRANSPORTATION2. Load the machine s

- Page 160 and 161:

TRANSPORTATIONTOWING MACHINEWhen to

- Page 162 and 163:

MAINTENANCECORRECT MAINTENANCE AND

- Page 164 and 165:

MAINTENANCELAYOUTMonoblock boomBuck

- Page 166 and 167:

MAINTENANCEMaintenance Guide TableS

- Page 168 and 169:

MAINTENANCEHOOD AND ACCESS COVERS11

- Page 170 and 171:

MAINTENANCEMAINTENANCE GUIDEA. GREA

- Page 172 and 173:

F. HYDRAULIC SYSTEM (See Page 7-37)

- Page 174 and 175:

Brand Names of Recommended GreaseWh

- Page 176 and 177:

MAINTENANCEA. GREASINGFront Joint P

- Page 178 and 179:

MEMOMAINTENANCE....................

- Page 180 and 181:

MAINTENANCESwing Internal Gear ---

- Page 182 and 183:

MAINTENANCEPropel Shaft (Front and

- Page 184 and 185:

MAINTENANCEB. ENGINEEngine Oil Leve

- Page 186 and 187:

MAINTENANCE11. Open the right and l

- Page 188 and 189:

MAINTENANCESwing Reduction GearChec

- Page 190 and 191: MAINTENANCEFront AxleCAUTION: The c

- Page 192 and 193: MAINTENANCEFront and Rear Hub Reduc

- Page 194 and 195: MAINTENANCECheck Brake Accumulator1

- Page 196 and 197: MAINTENANCEE. TIRETire/SizeUse tire

- Page 198 and 199: MAINTENANCEF. HYDRAULIC SYSTEMINSPE

- Page 200 and 201: REPLACEMENT OF HYDRAULIC OIL ANDFIL

- Page 202 and 203: MAINTENANCEDrain Hydraulic Oil Tank

- Page 204 and 205: MAINTENANCEBleed Air from Hydraulic

- Page 206 and 207: MAINTENANCEClean the Suction Filter

- Page 208 and 209: MAINTENANCEReplace Full-Flow Filter

- Page 210 and 211: MAINTENANCEReplace Air Breather Ele

- Page 212 and 213: MAINTENANCECheck Hoses and Lines---

- Page 214 and 215: MAINTENANCETable 2. LinesInterval(h

- Page 216 and 217: MAINTENANCEMetal Face Seal Fittings

- Page 218 and 219: MAINTENANCENOTE: Take precautions f

- Page 220 and 221: MAINTENANCEBleed Air from Fuel Syst

- Page 222 and 223: MAINTENANCEClean Feed Pump Strainer

- Page 224 and 225: MAINTENANCEH. AIR CLEANERClean Air

- Page 226 and 227: MAINTENANCEI. COOLING SYSTEMCoolant

- Page 228 and 229: MAINTENANCEChange Coolant--- twice

- Page 230 and 231: MAINTENANCEJ. ELECTRICAL SYSTEMIMPO

- Page 232 and 233: MAINTENANCEElectrolyte Level Check

- Page 234 and 235: MAINTENANCEREPLACING FUSESIf any el

- Page 236 and 237: MAINTENANCEK. MISCELLANEOUS1 4 5Che

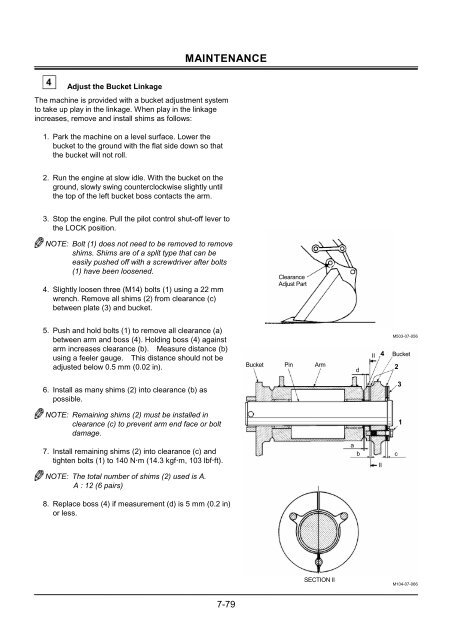

- Page 238 and 239: MAINTENANCEChange BucketCAUTION: Wh

- Page 242 and 243: MAINTENANCEClean and Replace Air Co

- Page 244 and 245: MAINTENANCECheck the Air Conditione

- Page 246 and 247: MAINTENANCECheck Injection Nozzle--

- Page 248 and 249: MAINTENANCECheck Tightening Torque

- Page 250 and 251: MAINTENANCECheck Tightening Torque

- Page 252 and 253: MAINTENANCE1. Retighten the engine

- Page 254 and 255: MAINTENANCE10. Retighten the swing

- Page 256 and 257: MAINTENANCE17. Retighten propel sha

- Page 258 and 259: MEMOMAINTENANCE....................

- Page 260 and 261: MEMOMAINTENANCE UNDER SPECIAL ENVIR

- Page 262 and 263: STORAGEREMOVING THE MACHINE FROM ST

- Page 264 and 265: TROUBLESHOOTING3. Engine is hard to

- Page 266 and 267: TROUBLESHOOTINGProblem Cause Soluti

- Page 268 and 269: TROUBLESHOOTINGBrakeProblem Cause S

- Page 270 and 271: TROUBLESHOOTING8. Engine SpeedProbl

- Page 272 and 273: SPECIFICATIONSSpecificationsZAXIS13

- Page 274 and 275: SPECIFICATIONSSpecificationsZAXIS13

- Page 276 and 277: SPECIFICATIONSWORKING RANGESZAXIS13

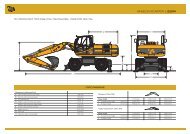

- Page 278 and 279: SPECIFICATIONSSPECIFICATIONSZAXIS16

- Page 280 and 281: SpecificationsZAXIS160W (FRONT BLAD

- Page 282 and 283: SPECIFICATIONSSpecificationsZAXIS16

- Page 284 and 285: BUCKET TYPES AND APPLICATIONSZAXIS1

- Page 286 and 287: SPECIFICATIONSSpecificationsZAXIS18

- Page 288 and 289: SPECIFICATIONSSpecificationsZAXIS18

- Page 290 and 291:

SPECIFICATIONSWORKING RANGESZAXIS18

- Page 292 and 293:

SPECIFICATIONSSPECIFICATIONSZAXIS21

- Page 294 and 295:

SpecificationsZAXIS210W (FRONT BLAD

- Page 296 and 297:

SPECIFICATIONSSpecificationsZAXIS21

- Page 298 and 299:

BUCKET TYPES AND APPLICATIONSZAXIS2

- Page 300 and 301:

OPTIONAL ATTACHMENTS AND DEVICES"#

- Page 302 and 303:

OPTIONAL ATTACHMENTS AND DEVICESSta

- Page 304 and 305:

ATTACHMENT PEDAL (BREAKER)(Optional

- Page 306 and 307:

OPTIONAL ATTACHMENTS AND DEVICES•

- Page 308 and 309:

ATTACHMENT PEDAL(HYDRAULIC CRUSHER)

- Page 310 and 311:

OPTIONAL ATTACHMENTS AND DEVICESELE

- Page 312 and 313:

OPTIONAL ATTACHMENTS AND DEVICESIf

- Page 314 and 315:

OPTIONAL ATTACHMENTS AND DEVICESADD

- Page 316 and 317:

MEMOOPTIONAL ATTACHMENTS AND DEVICE

- Page 318 and 319:

INDEXGGeneral Precautions for Cab..