Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

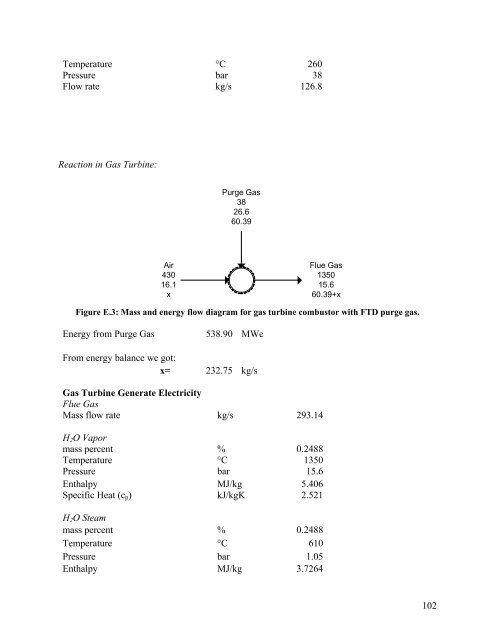

Temperature °C 260<br />

Pressure bar 38<br />

Flow rate kg/s 126.8<br />

Reaction in Gas Turbine:<br />

Air<br />

430<br />

16.1<br />

x<br />

Purge Gas<br />

38<br />

26.6<br />

60.39<br />

Flue Gas<br />

1350<br />

15.6<br />

60.39+x<br />

Figure E.3: Mass <strong>an</strong>d energy flow diagram <strong>for</strong> gas turbine combustor with FTD purge gas.<br />

Energy from Purge Gas 538.90 MWe<br />

From energy bal<strong>an</strong>ce we got:<br />

x= 232.75 kg/s<br />

Gas Turbine Generate Electricity<br />

Flue Gas<br />

Mass flow rate kg/s 293.14<br />

H2O Vapor<br />

mass percent % 0.2488<br />

Temperature °C 1350<br />

Pressure bar 15.6<br />

Enthalpy MJ/kg 5.406<br />

Specific Heat (cp) kJ/kgK 2.521<br />

H2O Steam<br />

mass percent % 0.2488<br />

Temperature °C 610<br />

Pressure bar 1.05<br />

Enthalpy MJ/kg 3.7264<br />

102