Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>for</strong>ce. Washing is broken up into five individual stages: dilution, mixing, dewatering, diffusion,<br />

<strong>an</strong>d displacement. The water used <strong>for</strong> this process is ga<strong>the</strong>red from <strong>the</strong> drying <strong>an</strong>d evaporation<br />

stages.<br />

The first stage typically uses <strong>an</strong> acidic solution which binds to <strong>the</strong> lignin. In between each<br />

bleaching stage, <strong>the</strong> chemicals are drained from <strong>the</strong> pulp <strong>an</strong>d it is <strong>the</strong>n washed with <strong>the</strong><br />

a<strong>for</strong>ementioned water. Only in <strong>the</strong> last acid <strong>an</strong>d alkaline stages does <strong>the</strong> water have to be pure.<br />

Next, <strong>the</strong> lignin acid is removed in <strong>an</strong> E stage with sodium hydroxide. At <strong>the</strong> end <strong>of</strong> <strong>the</strong> process,<br />

<strong>the</strong> pulp is whitened by sodium hypochlorite, chlorine dioxide, or hydrogen peroxide.<br />

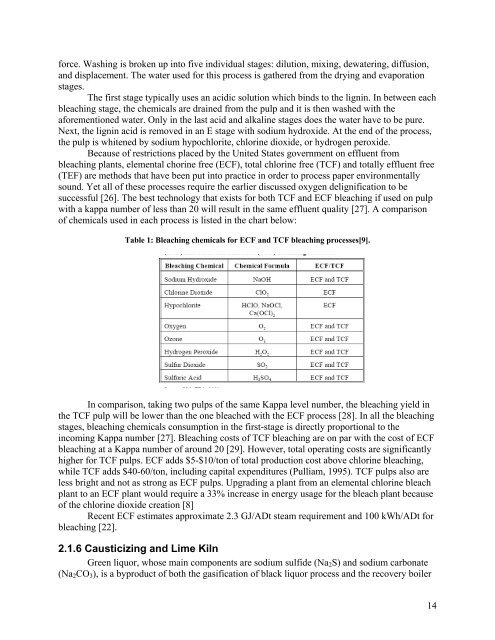

Because <strong>of</strong> restrictions placed by <strong>the</strong> United States government on effluent from<br />

bleaching pl<strong>an</strong>ts, elemental chorine free (ECF), total chlorine free (TCF) <strong>an</strong>d totally effluent free<br />

(TEF) are methods that have been put into practice in order to process paper environmentally<br />

sound. Yet all <strong>of</strong> <strong>the</strong>se processes require <strong>the</strong> earlier discussed oxygen delignification to be<br />

successful [26]. The best technology that exists <strong>for</strong> both TCF <strong>an</strong>d ECF bleaching if used on pulp<br />

with a kappa number <strong>of</strong> less th<strong>an</strong> 20 will result in <strong>the</strong> same effluent quality [27]. A comparison<br />

<strong>of</strong> chemicals used in each process is listed in <strong>the</strong> chart below:<br />

Table 1: Bleaching chemicals <strong>for</strong> ECF <strong>an</strong>d TCF bleaching processes[9].<br />

In comparison, taking two pulps <strong>of</strong> <strong>the</strong> same Kappa level number, <strong>the</strong> bleaching yield in<br />

<strong>the</strong> TCF pulp will be lower th<strong>an</strong> <strong>the</strong> one bleached with <strong>the</strong> ECF process [28]. In all <strong>the</strong> bleaching<br />

stages, bleaching chemicals consumption in <strong>the</strong> first-stage is directly proportional to <strong>the</strong><br />

incoming Kappa number [27]. Bleaching costs <strong>of</strong> TCF bleaching are on par with <strong>the</strong> cost <strong>of</strong> ECF<br />

bleaching at a Kappa number <strong>of</strong> around 20 [29]. However, total operating costs are signific<strong>an</strong>tly<br />

higher <strong>for</strong> TCF pulps. ECF adds $5-$10/ton <strong>of</strong> total production cost above chlorine bleaching,<br />

while TCF adds $40-60/ton, including capital expenditures (Pulliam, 1995). TCF pulps also are<br />

less bright <strong>an</strong>d not as strong as ECF pulps. Upgrading a pl<strong>an</strong>t from <strong>an</strong> elemental chlorine bleach<br />

pl<strong>an</strong>t to <strong>an</strong> ECF pl<strong>an</strong>t would require a 33% increase in energy usage <strong>for</strong> <strong>the</strong> bleach pl<strong>an</strong>t because<br />

<strong>of</strong> <strong>the</strong> chlorine dioxide creation [8]<br />

Recent ECF estimates approximate 2.3 GJ/ADt steam requirement <strong>an</strong>d 100 kWh/ADt <strong>for</strong><br />

bleaching [22].<br />

2.1.6 Causticizing <strong>an</strong>d Lime Kiln<br />

Green liquor, whose main components are sodium sulfide (Na2S) <strong>an</strong>d sodium carbonate<br />

(Na2CO3), is a byproduct <strong>of</strong> both <strong>the</strong> gasification <strong>of</strong> black liquor process <strong>an</strong>d <strong>the</strong> recovery boiler<br />

14