Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

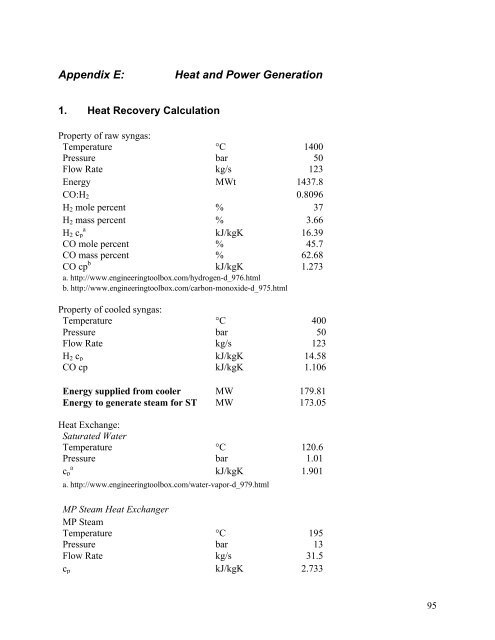

Appendix E: Heat <strong>an</strong>d Power Generation<br />

1. Heat Recovery Calculation<br />

Property <strong>of</strong> raw syngas:<br />

Temperature °C 1400<br />

Pressure bar 50<br />

Flow Rate kg/s 123<br />

Energy MWt 1437.8<br />

CO:H2 0.8096<br />

H2 mole percent % 37<br />

H2 mass percent % 3.66<br />

H2 cp a kJ/kgK 16.39<br />

CO mole percent % 45.7<br />

CO mass percent % 62.68<br />

CO cp b kJ/kgK 1.273<br />

a. http://www.engineeringtoolbox.com/hydrogen-d_976.html<br />

b. http://www.engineeringtoolbox.com/carbon-monoxide-d_975.html<br />

Property <strong>of</strong> cooled syngas:<br />

Temperature °C 400<br />

Pressure bar 50<br />

Flow Rate kg/s 123<br />

H2 cp kJ/kgK 14.58<br />

CO cp kJ/kgK 1.106<br />

Energy supplied from cooler MW 179.81<br />

Energy to generate steam <strong>for</strong> ST MW 173.05<br />

Heat Exch<strong>an</strong>ge:<br />

Saturated Water<br />

Temperature °C 120.6<br />

Pressure bar 1.01<br />

cp a kJ/kgK 1.901<br />

a. http://www.engineeringtoolbox.com/water-vapor-d_979.html<br />

MP Steam Heat Exch<strong>an</strong>ger<br />

MP Steam<br />

Temperature °C 195<br />

Pressure bar 13<br />

Flow Rate kg/s 31.5<br />

cp kJ/kgK 2.733<br />

95