Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

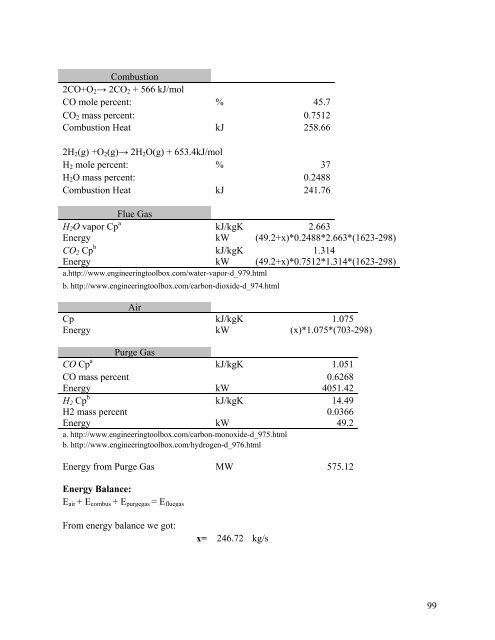

Combustion<br />

2CO+O2→ 2CO2 + 566 kJ/mol<br />

CO mole percent: % 45.7<br />

CO2 mass percent: 0.7512<br />

Combustion Heat kJ 258.66<br />

2H2(g) +O2(g)→ 2H2O(g) + 653.4kJ/mol<br />

H2 mole percent: % 37<br />

H2O mass percent: 0.2488<br />

Combustion Heat kJ 241.76<br />

Flue Gas<br />

H2O vapor Cp a kJ/kgK 2.663<br />

Energy kW (49.2+x)*0.2488*2.663*(1623-298)<br />

CO2 Cp b kJ/kgK 1.314<br />

Energy kW (49.2+x)*0.7512*1.314*(1623-298)<br />

a.http://www.engineeringtoolbox.com/water-vapor-d_979.html<br />

b. http://www.engineeringtoolbox.com/carbon-dioxide-d_974.html<br />

Air<br />

Cp kJ/kgK 1.075<br />

Energy kW (x)*1.075*(703-298)<br />

Purge Gas<br />

CO Cp a kJ/kgK 1.051<br />

CO mass percent 0.6268<br />

Energy kW 4051.42<br />

H2 Cp b kJ/kgK 14.49<br />

H2 mass percent 0.0366<br />

Energy kW 49.2<br />

a. http://www.engineeringtoolbox.com/carbon-monoxide-d_975.html<br />

b. http://www.engineeringtoolbox.com/hydrogen-d_976.html<br />

Energy from Purge Gas MW 575.12<br />

Energy Bal<strong>an</strong>ce:<br />

Eair + Ecombus + Epurgegas = Efluegas<br />

From energy bal<strong>an</strong>ce we got:<br />

x= 246.72 kg/s<br />

99