Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.5 Heat <strong>an</strong>d Power Generation Process <strong>Design</strong><br />

3.5.1 Heat Recovery System <strong>Design</strong><br />

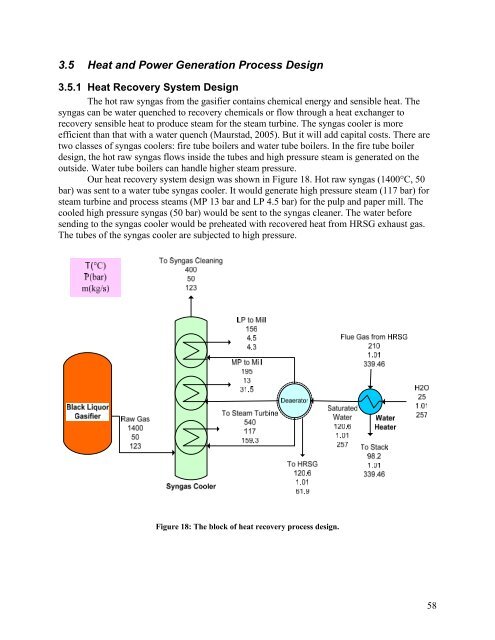

The hot raw syngas from <strong>the</strong> gasifier contains chemical energy <strong>an</strong>d sensible heat. The<br />

syngas c<strong>an</strong> be water quenched to recovery chemicals or flow through a heat exch<strong>an</strong>ger to<br />

recovery sensible heat to produce steam <strong>for</strong> <strong>the</strong> steam turbine. The syngas cooler is more<br />

efficient th<strong>an</strong> that with a water quench (Maurstad, 2005). But it will add capital costs. There are<br />

two classes <strong>of</strong> syngas coolers: fire tube boilers <strong>an</strong>d water tube boilers. In <strong>the</strong> fire tube boiler<br />

design, <strong>the</strong> hot raw syngas flows inside <strong>the</strong> tubes <strong>an</strong>d high pressure steam is generated on <strong>the</strong><br />

outside. Water tube boilers c<strong>an</strong> h<strong>an</strong>dle higher steam pressure.<br />

Our heat recovery system design was shown in Figure 18. Hot raw syngas (1400°C, 50<br />

bar) was sent to a water tube syngas cooler. It would generate high pressure steam (117 bar) <strong>for</strong><br />

steam turbine <strong>an</strong>d process steams (MP 13 bar <strong>an</strong>d LP 4.5 bar) <strong>for</strong> <strong>the</strong> pulp <strong>an</strong>d paper mill. The<br />

cooled high pressure syngas (50 bar) would be sent to <strong>the</strong> syngas cle<strong>an</strong>er. The water be<strong>for</strong>e<br />

sending to <strong>the</strong> syngas cooler would be preheated with recovered heat from HRSG exhaust gas.<br />

The tubes <strong>of</strong> <strong>the</strong> syngas cooler are subjected to high pressure.<br />

Figure 18: The block <strong>of</strong> heat recovery process design.<br />

58