Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

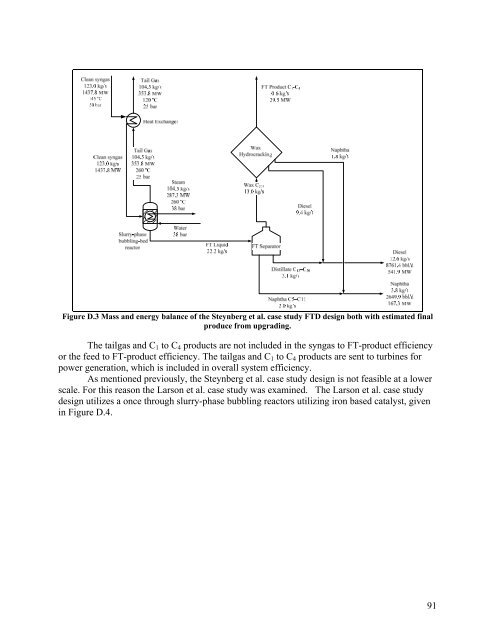

Figure D.3 Mass <strong>an</strong>d energy bal<strong>an</strong>ce <strong>of</strong> <strong>the</strong> Steynberg et al. case study FTD design both with estimated final<br />

produce from upgrading.<br />

The tailgas <strong>an</strong>d C1 to C4 products are not included in <strong>the</strong> syngas to FT-product efficiency<br />

or <strong>the</strong> feed to FT-product efficiency. The tailgas <strong>an</strong>d C1 to C4 products are sent to turbines <strong>for</strong><br />

power generation, which is included in overall system efficiency.<br />

As mentioned previously, <strong>the</strong> Steynberg et al. case study design is not feasible at a lower<br />

scale. For this reason <strong>the</strong> Larson et al. case study was examined. The Larson et al. case study<br />

design utilizes a once through slurry-phase bubbling reactors utilizing iron based catalyst, given<br />

in Figure D.4.<br />

91