Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

124,228 GJ/day (1,990 MW) <strong>of</strong> syngas energy, or a syngas mass flow rate <strong>of</strong> 123 kg/s. In order<br />

to determine <strong>the</strong> amount <strong>of</strong> gasifier input fuel required to produce 123 kg/s <strong>of</strong> syngas, actual<br />

syngas yields from a coal-fed Texaco gasifier were found <strong>for</strong> gasifier oxygen-to-fuel ratios<br />

similar to <strong>the</strong> parameters <strong>for</strong> this design project. For oxygen-fuel ratios near 0.9, <strong>the</strong> average fuel<br />

to syn<strong>the</strong>sis gas ratio was 0.535. Detailed calculations are included in Appendix D.<br />

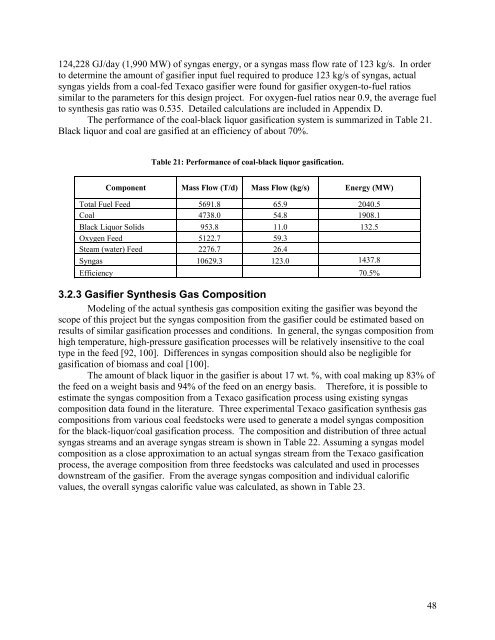

The per<strong>for</strong>m<strong>an</strong>ce <strong>of</strong> <strong>the</strong> coal-black liquor gasification system is summarized in Table 21.<br />

Black liquor <strong>an</strong>d coal are gasified at <strong>an</strong> efficiency <strong>of</strong> about 70%.<br />

Table 21: Per<strong>for</strong>m<strong>an</strong>ce <strong>of</strong> coal-black liquor gasification.<br />

Component Mass Flow (T/d) Mass Flow (kg/s) Energy (MW)<br />

Total Fuel Feed 5691.8 65.9 2040.5<br />

Coal 4738.0 54.8 1908.1<br />

Black Liquor Solids 953.8 11.0 132.5<br />

Oxygen Feed 5122.7 59.3<br />

Steam (water) Feed 2276.7 26.4<br />

Syngas 10629.3 123.0 1437.8<br />

Efficiency 70.5%<br />

3.2.3 Gasifier Syn<strong>the</strong>sis Gas Composition<br />

Modeling <strong>of</strong> <strong>the</strong> actual syn<strong>the</strong>sis gas composition exiting <strong>the</strong> gasifier was beyond <strong>the</strong><br />

scope <strong>of</strong> this project but <strong>the</strong> syngas composition from <strong>the</strong> gasifier could be estimated based on<br />

results <strong>of</strong> similar gasification processes <strong>an</strong>d conditions. In general, <strong>the</strong> syngas composition from<br />

high temperature, high-pressure gasification processes will be relatively insensitive to <strong>the</strong> coal<br />

type in <strong>the</strong> feed [92, 100]. Differences in syngas composition should also be negligible <strong>for</strong><br />

gasification <strong>of</strong> biomass <strong>an</strong>d coal [100].<br />

The amount <strong>of</strong> black liquor in <strong>the</strong> gasifier is about 17 wt. %, with coal making up 83% <strong>of</strong><br />

<strong>the</strong> feed on a weight basis <strong>an</strong>d 94% <strong>of</strong> <strong>the</strong> feed on <strong>an</strong> energy basis. There<strong>for</strong>e, it is possible to<br />

estimate <strong>the</strong> syngas composition from a Texaco gasification process using existing syngas<br />

composition data found in <strong>the</strong> literature. Three experimental Texaco gasification syn<strong>the</strong>sis gas<br />

compositions from various coal feedstocks were used to generate a model syngas composition<br />

<strong>for</strong> <strong>the</strong> black-liquor/coal gasification process. The composition <strong>an</strong>d distribution <strong>of</strong> three actual<br />

syngas streams <strong>an</strong>d <strong>an</strong> average syngas stream is shown in Table 22. Assuming a syngas model<br />

composition as a close approximation to <strong>an</strong> actual syngas stream from <strong>the</strong> Texaco gasification<br />

process, <strong>the</strong> average composition from three feedstocks was calculated <strong>an</strong>d used in processes<br />

downstream <strong>of</strong> <strong>the</strong> gasifier. From <strong>the</strong> average syngas composition <strong>an</strong>d individual calorific<br />

values, <strong>the</strong> overall syngas calorific value was calculated, as shown in Table 23.<br />

48