Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.3.2.4 CO conversion <strong>an</strong>d efficiency<br />

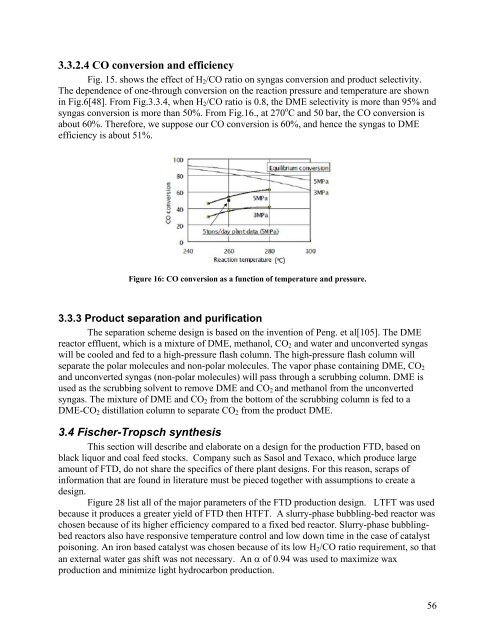

Fig. 15. shows <strong>the</strong> effect <strong>of</strong> H2/CO ratio on syngas conversion <strong>an</strong>d product selectivity.<br />

The dependence <strong>of</strong> one-through conversion on <strong>the</strong> reaction pressure <strong>an</strong>d temperature are shown<br />

in Fig.6[48]. From Fig.3.3.4, when H2/CO ratio is 0.8, <strong>the</strong> DME selectivity is more th<strong>an</strong> 95% <strong>an</strong>d<br />

syngas conversion is more th<strong>an</strong> 50%. From Fig.16., at 270 o C <strong>an</strong>d 50 bar, <strong>the</strong> CO conversion is<br />

about 60%. There<strong>for</strong>e, we suppose our CO conversion is 60%, <strong>an</strong>d hence <strong>the</strong> syngas to DME<br />

efficiency is about 51%.<br />

Figure 16: CO conversion as a function <strong>of</strong> temperature <strong>an</strong>d pressure.<br />

3.3.3 Product separation <strong>an</strong>d purification<br />

The separation scheme design is based on <strong>the</strong> invention <strong>of</strong> Peng. et al[105]. The DME<br />

reactor effluent, which is a mixture <strong>of</strong> DME, meth<strong>an</strong>ol, CO2 <strong>an</strong>d water <strong>an</strong>d unconverted syngas<br />

will be cooled <strong>an</strong>d fed to a high-pressure flash column. The high-pressure flash column will<br />

separate <strong>the</strong> polar molecules <strong>an</strong>d non-polar molecules. The vapor phase containing DME, CO2<br />

<strong>an</strong>d unconverted syngas (non-polar molecules) will pass through a scrubbing column. DME is<br />

used as <strong>the</strong> scrubbing solvent to remove DME <strong>an</strong>d CO2 <strong>an</strong>d meth<strong>an</strong>ol from <strong>the</strong> unconverted<br />

syngas. The mixture <strong>of</strong> DME <strong>an</strong>d CO2 from <strong>the</strong> bottom <strong>of</strong> <strong>the</strong> scrubbing column is fed to a<br />

DME-CO2 distillation column to separate CO2 from <strong>the</strong> product DME.<br />

3.4 Fischer-Tropsch syn<strong>the</strong>sis<br />

This section will describe <strong>an</strong>d elaborate on a design <strong>for</strong> <strong>the</strong> production FTD, based on<br />

black liquor <strong>an</strong>d coal feed stocks. Comp<strong>an</strong>y such as Sasol <strong>an</strong>d Texaco, which produce large<br />

amount <strong>of</strong> FTD, do not share <strong>the</strong> specifics <strong>of</strong> <strong>the</strong>re pl<strong>an</strong>t designs. For this reason, scraps <strong>of</strong><br />

in<strong>for</strong>mation that are found in literature must be pieced toge<strong>the</strong>r with assumptions to create a<br />

design.<br />

Figure 28 list all <strong>of</strong> <strong>the</strong> major parameters <strong>of</strong> <strong>the</strong> FTD production design. LTFT was used<br />

because it produces a greater yield <strong>of</strong> FTD <strong>the</strong>n HTFT. A slurry-phase bubbling-bed reactor was<br />

chosen because <strong>of</strong> its higher efficiency compared to a fixed bed reactor. Slurry-phase bubblingbed<br />

reactors also have responsive temperature control <strong>an</strong>d low down time in <strong>the</strong> case <strong>of</strong> catalyst<br />

poisoning. An iron based catalyst was chosen because <strong>of</strong> its low H2/CO ratio requirement, so that<br />

<strong>an</strong> external water gas shift was not necessary. An α <strong>of</strong> 0.94 was used to maximize wax<br />

production <strong>an</strong>d minimize light hydrocarbon production.<br />

56