Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

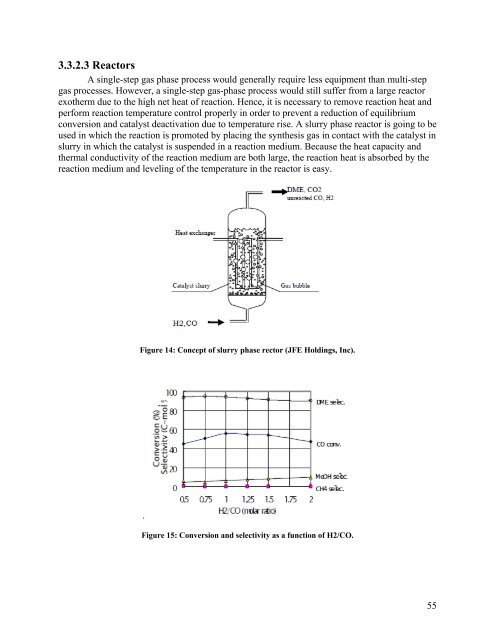

3.3.2.3 Reactors<br />

A single-step gas phase process would generally require less equipment th<strong>an</strong> multi-step<br />

gas processes. However, a single-step gas-phase process would still suffer from a large reactor<br />

exo<strong>the</strong>rm due to <strong>the</strong> high net heat <strong>of</strong> reaction. Hence, it is necessary to remove reaction heat <strong>an</strong>d<br />

per<strong>for</strong>m reaction temperature control properly in order to prevent a reduction <strong>of</strong> equilibrium<br />

conversion <strong>an</strong>d catalyst deactivation due to temperature rise. A slurry phase reactor is going to be<br />

used in which <strong>the</strong> reaction is promoted by placing <strong>the</strong> syn<strong>the</strong>sis gas in contact with <strong>the</strong> catalyst in<br />

slurry in which <strong>the</strong> catalyst is suspended in a reaction medium. Because <strong>the</strong> heat capacity <strong>an</strong>d<br />

<strong>the</strong>rmal conductivity <strong>of</strong> <strong>the</strong> reaction medium are both large, <strong>the</strong> reaction heat is absorbed by <strong>the</strong><br />

reaction medium <strong>an</strong>d leveling <strong>of</strong> <strong>the</strong> temperature in <strong>the</strong> reactor is easy.<br />

Figure 14: Concept <strong>of</strong> slurry phase rector (JFE Holdings, Inc).<br />

.<br />

Figure 15: Conversion <strong>an</strong>d selectivity as a function <strong>of</strong> H2/CO.<br />

55